Precision in Motion: The Rise of Non-Magnetic Compact Cylinders

“Ideal for sensitive environments, these cylinders deliver powerful performance without magnetic interference. They are compact, clean, and reliable.”

With present-day automation and industrial applications, a greater demand than ever is placed on high-performing, compact-sized components. Among those components is the Non-Magnetic Compact Cylinder—an innovative, magnetism-avoiding pneumatic actuator purpose-designed for situations where magnetic interference must be excluded. Vinod Gautam Sales, a trusted name in pneumatic innovation, is at the forefront of delivering these high-performance actuators that combine strength and precision in a small footprint. Applications span across medical device manufacture, electronics assembly, and cleanroom automation.

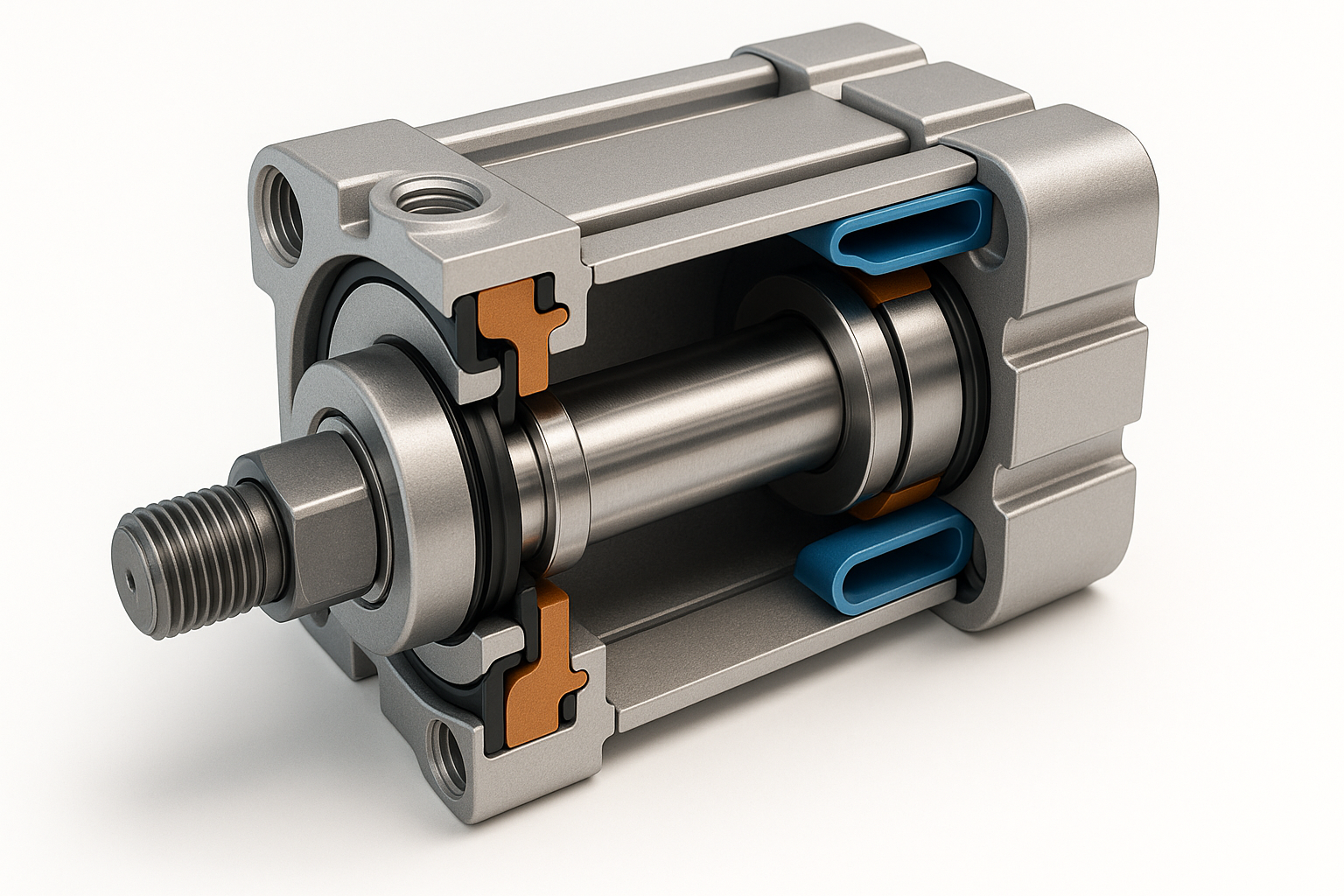

In contrast to conventional cylinders that utilize magnetic pistons to sense position, Vinod Gautam Sales’ non-magnetic compact cylinders are produced without any magnetic material. This gives them a unique role in scenarios where even minimal magnetic fields could disrupt sensitive operations, such as MRI suites or data-sensitive environments. With Vinod Gautam Sales cylinders, industries can ensure safe, precise motion control without risking magnetic interference.

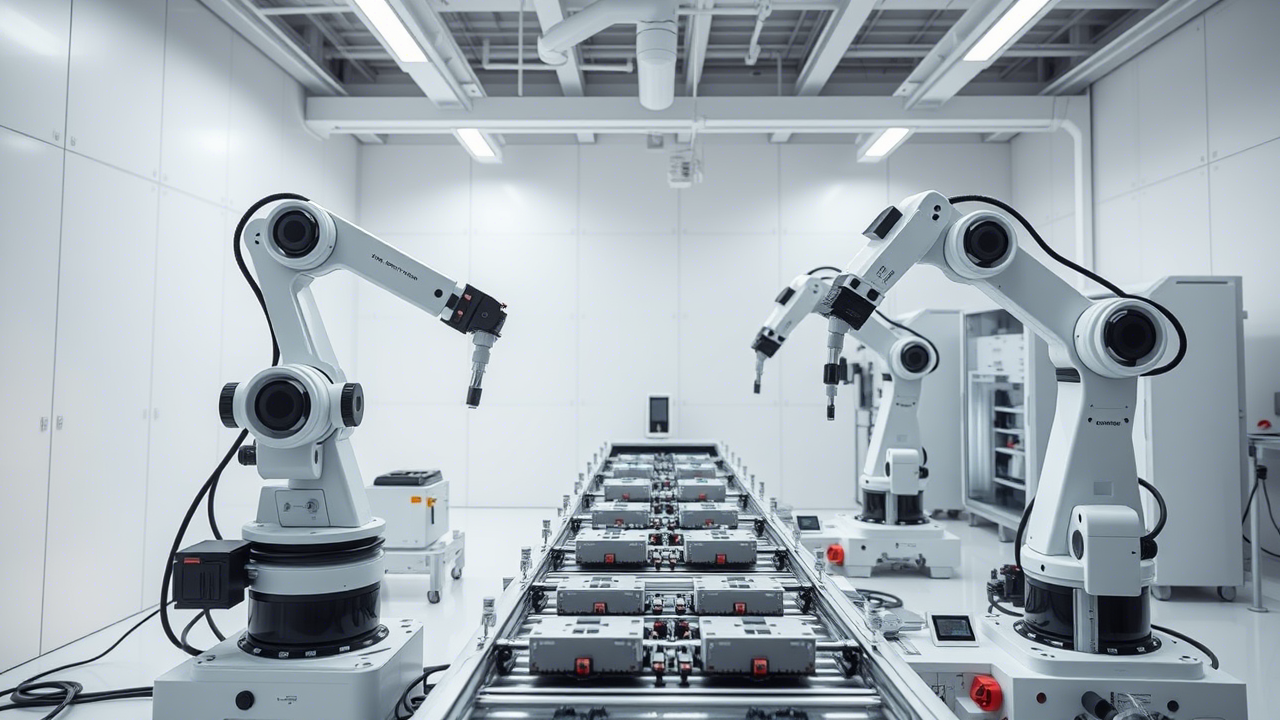

Another defining advantage of Vinod Gautam Sales’s non-magnetic cylinders is their compact size. Space constraints are common across industrial setups, and large actuators may not always be viable. VGS compact cylinders are engineered to deliver the same output force as larger units while taking up significantly less space—ideal for robotic arms and automated systems where precision must coexist with limited room.

From a performance perspective, Vinod Gautam Sales cylinders are rugged and reliable. Crafted with high-grade materials, they are built to endure high pressures, vibrations, and fluctuating temperatures. Their sealed design ensures low contamination, making them perfect for sterile or controlled environments like pharmaceutical manufacturing and food packaging plants.

One of the greatest benefits of using Vinod Gautam Sales’ non-magnetic compact cylinders is their minimal maintenance requirements. With no magnetic components, the risk of damage from metal particles or magnetic debris is eliminated. This extends service intervals and reduces downtime, supporting continuous productivity. Their simple yet effective design makes integration into existing pneumatic systems seamless.

As industries embrace trends in automation, miniaturization, and operational efficiency, Vinod Gautam Sales’ non-magnetic cylinders emerge as enablers of next-gen manufacturing. They meet the critical demands of space-saving design without compromising on performance or safety, offering a competitive edge in today’s precision-driven environments.

In summary, Vinod Gautam Sales’ non-magnetic compact cylinders are more than space-efficient—they are performance-enhancing assets. Their cutting-edge design, reliability, and non-interfering operation make them ideal for any setting where accuracy, safety, and efficiency are non-negotiable. Whether in a cleanroom, hospital, or high-tech production facility, VGS cylinders can elevate your operations—efficiently and noiselessly, stroke after stroke.