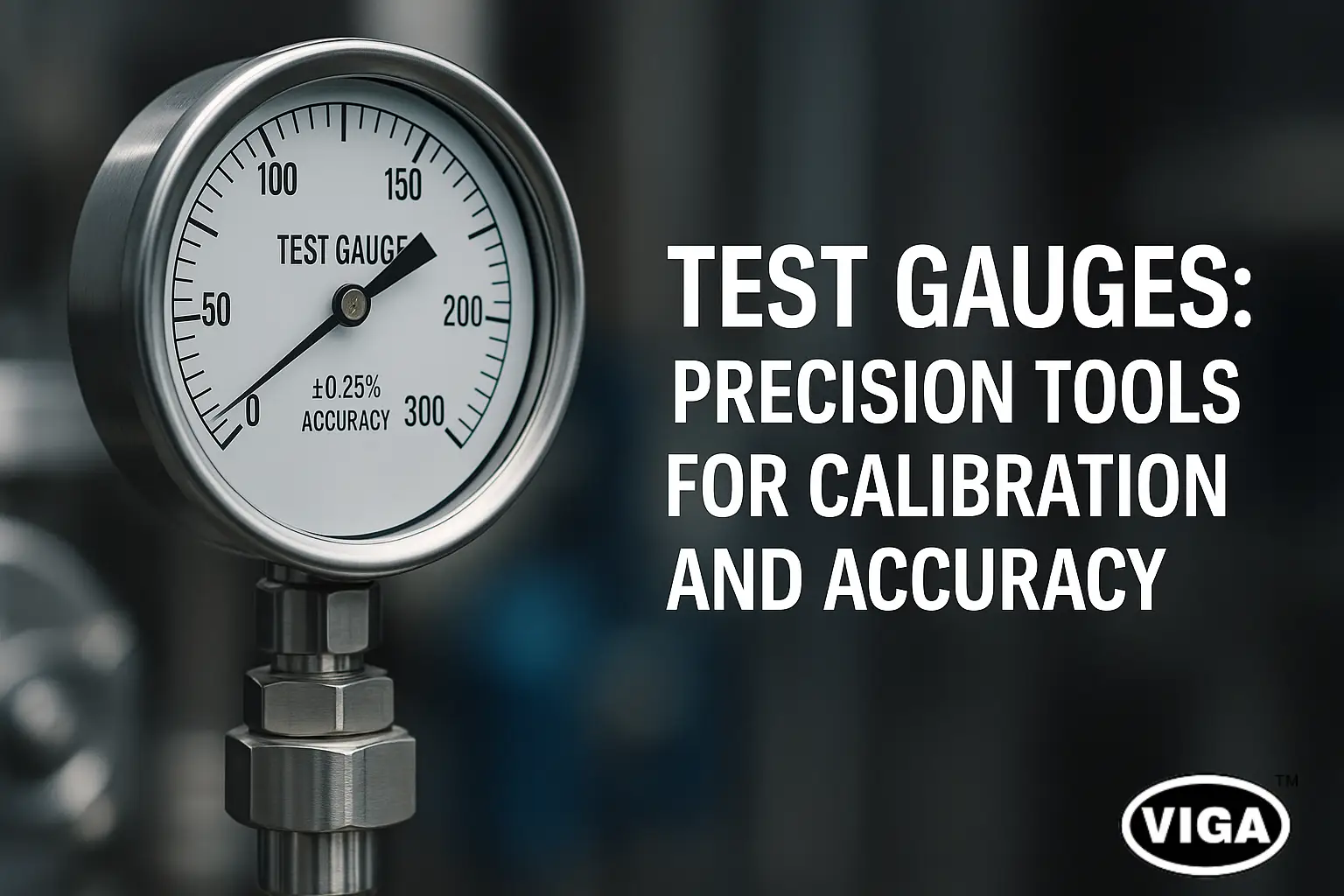

Test Gauges: Precision Tools for Calibration and Accuracy

Test Gauges: Precision Instruments for Calibration & Accuracy Checks

In engineering and industrial operations, there’s a saying: “If you can’t measure it correctly, you can’t control it correctly.” No matter how advanced a process is, its success ultimately depends on the accuracy of its measurements. For industries such as pharmaceuticals, oil and gas, chemicals, automotive, and utilities, reliable readings of pressure, temperature, and flow mean the difference between consistent quality and serious system failure.

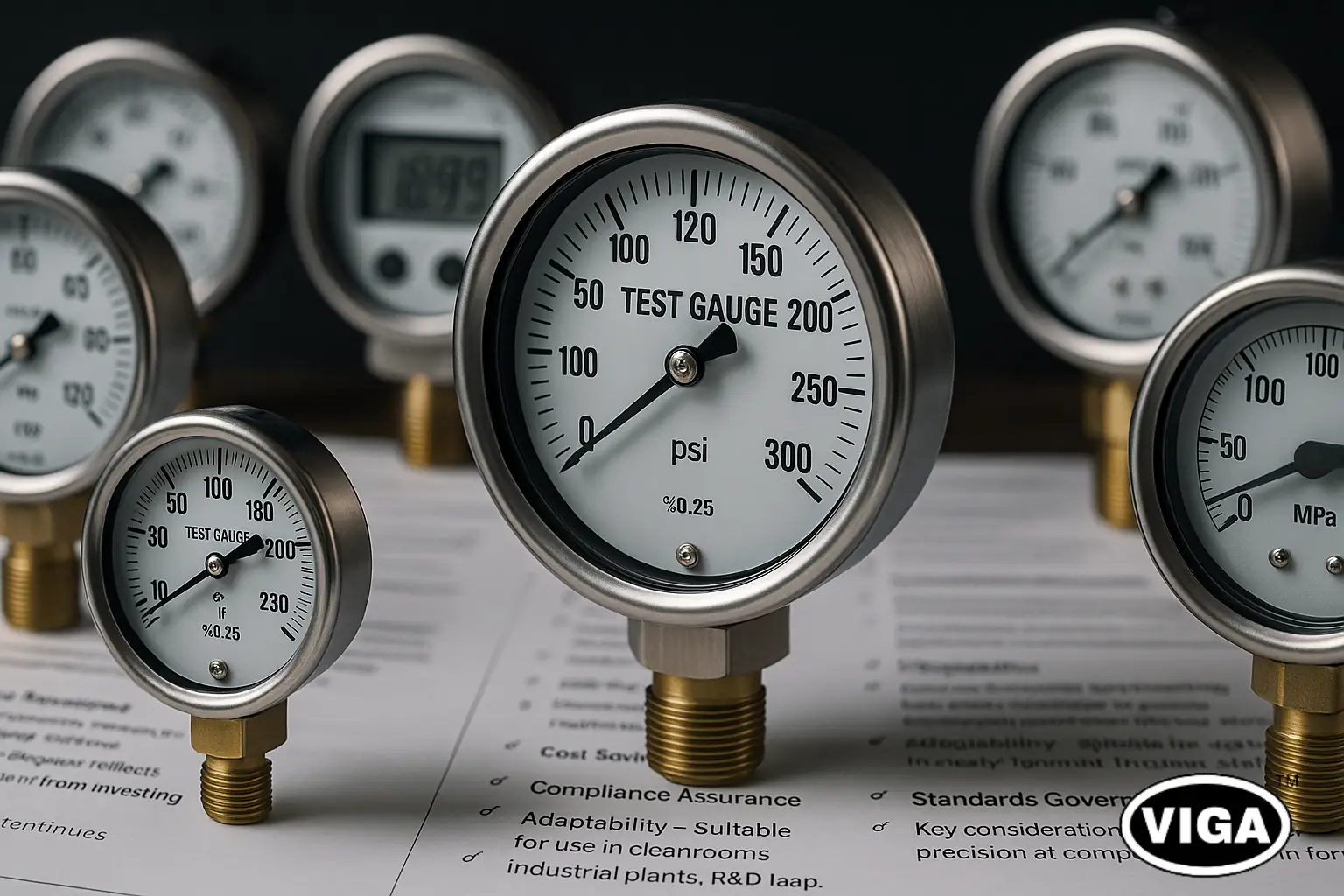

When accuracy is critical, industries turn to one tool above all others: test gauges. These instruments are not everyday operational gauges, but specialized precision devices that act as benchmarks for calibration and verification. They confirm whether working instruments are trustworthy, identify inaccuracies that could lead to costly errors, and establish measurement traceability according to recognized standards.

This article examines test gauges in detail. We’ll cover their purpose, different types, applications across industries, technical benefits, compliance with global standards, trends in Indian manufacturing, and practical tips for choosing the right gauge.

What Exactly Are Test Gauges?

Test gauges are precision measuring instruments designed for one main purpose—calibration and validation. Where standard pressure gauges might give readings with a ±1% or ±2% accuracy, test gauges improve that figure dramatically, often down to ±0.25%, ±0.1%, or even tighter tolerances.

A useful way to describe test gauges is to call them “referees”. Just as referees ensure a fair game, test gauges ensure that every working instrument—whether it’s installed on a reactor, a pipeline, or a testing bench—is reading accurately. Whenever discrepancies arise, it’s the test gauge that reveals them.

Typical characteristics include:

- High-resolution scales, often with mirrored surfaces to eliminate parallax errors.

- Precision pointers for finer readability.

- Robust designs to minimize long-term drift in measurements.

- Traceable calibration certificates confirming compliance with ISO/IEC or ASME standards.

Categories of Test Gauges

Precision Test Gauges

These are the finest category of gauges, often used where measurement cannot tolerate the slightest deviation. Typical environments include aerospace engineering, defense equipment testing, high-tech laboratories, and nuclear facilities. For example, in an R&D lab testing rocket engine components, even a tiny pressure mismatch may skew results. Precision test gauges ensure readings remain unquestionably reliable.

Calibration Test Gauges

As the name suggests, calibration test gauges serve as references in calibration processes. Their role is to recalibrate or verify working gauges used in production and field work. Calibration facilities often link a calibration gauge with pumps, pressure controllers, or deadweight testers to compare readings across a defined range.

Accuracy Test Gauges

Accuracy test gauges represent a middle ground—they are not laboratory-grade, but they are portable, rugged, and suitable for field applications. Maintenance teams, for example, use them during scheduled shutdowns to spot-check operating gauges across plants.

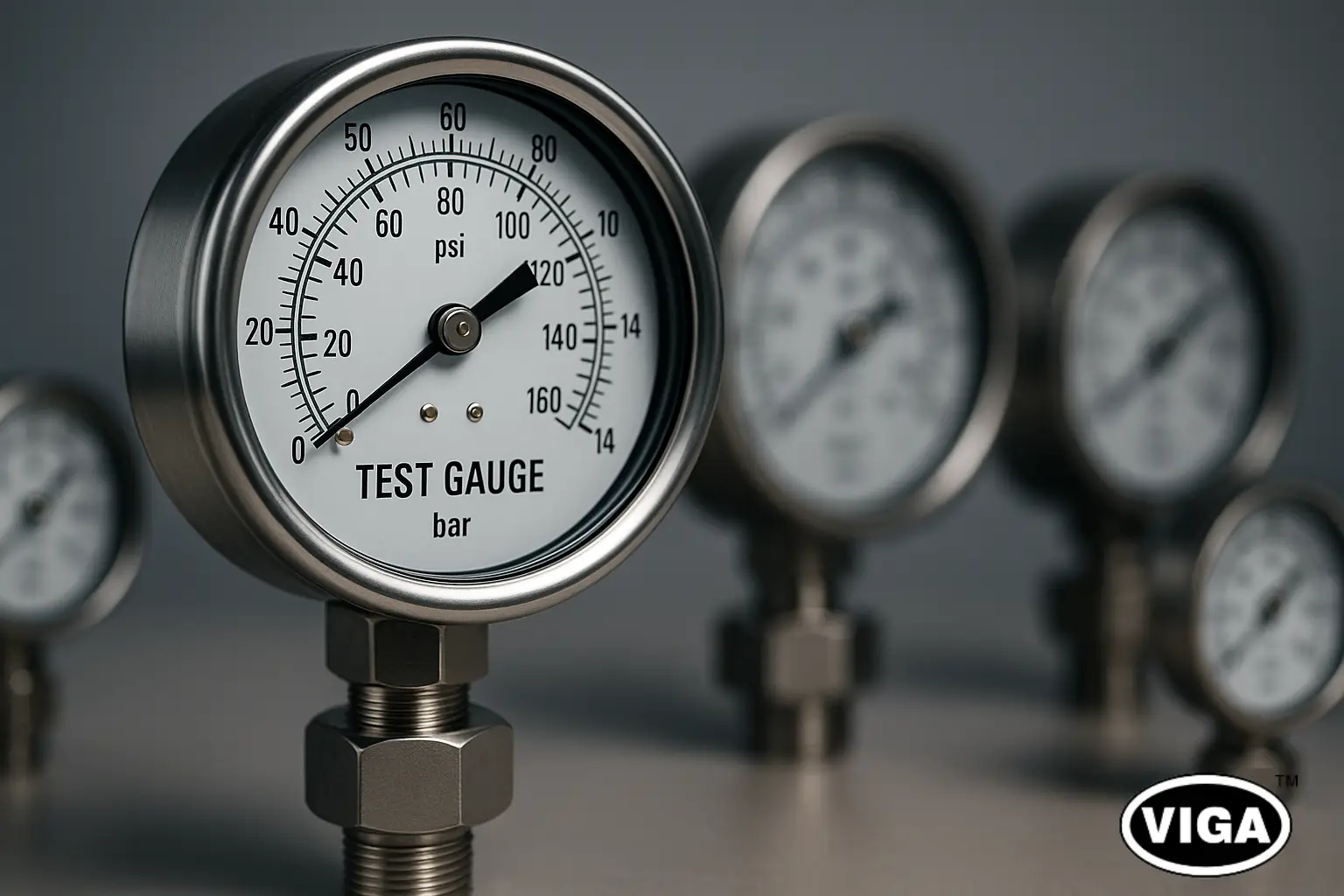

Pressure Test Gauges

These are the most widely used. Pressure test gauges validate pressure in mechanical, chemical, and hydraulic systems under real operational conditions. Available in sealed stainless steel, liquid-filled for vibration resistance, or diaphragm-protected configurations, they are indispensable across refineries, chemical plants, water treatment units, automotive hydraulics, and HVAC installations.

Applications of Test Gauges

Test gauges are universal in scope, spanning across industries and purposes.

Industrial Calibration

In large-scale industries such as steel manufacturing or petroleum processing, equipment often works under high pressures and extreme temperatures. Instruments installed in these systems gradually drift away from their calibration reference. Test gauges for industrial calibration ensure these deviations are detected and corrected before they compromise production safety or quality.

Laboratories

Laboratories, particularly in pharmaceuticals, biotechnology, and electronics, depend heavily on measurement accuracy. Test gauges in laboratories verify pressure in sterilizers, containment chambers, and controlled experimental setups. If a lab is conducting a test requiring pressure stability within ±0.2 bar, only a test gauge offers confidence that the values being recorded are accurate.

Manufacturing and Quality Assurance

Factories rely on test gauges to preserve quality assurance. In automotive plants, brake systems, fuel injectors, and hydraulic testing setups all undergo scrutiny with calibrated test gauges. The outcome ensures vehicles leave assembly lines compliant with safety regulations.

Utilities and Energy

Power generation is another sector that cannot risk inaccuracies. Whether in a thermal power plant measuring turbine steam pressure or a hydroelectric unit monitoring flow control mechanisms, test gauges maintain the delicate balance between efficiency, performance, and safety.

Aerospace and Defense

For aircraft manufacturers or defense organizations, measurement tolerances are extremely strict. Precision gauges are used in flight simulators, cabin pressurization tests, missile launch system verifications, and more. A misreading here could have consequences measured not in profits, but in lives.

Benefits of Test Gauges

A common question from plant managers is: “Why invest in test gauges when we already have operational gauges installed?” The answer becomes clear when considering the benefits.

- Unmatched Accuracy – With tolerance levels as low as ±0.1%, test gauges are several times more precise than regular gauges.

- Reliability in Calibration Chains – They form the backbone of calibration by providing a reference traceable to national or international standards.

- Enhanced Safety – Prevents critical equipment failures by verifying that operational gauges reflect true system conditions.

- Cost Savings Over Time – Downtime, rejected batches, or safety breaches cost much more than investing in proper test equipment.

- Compliance Assurance – ISO-certified processes and industries under FDA or BIS regulations all require calibration using traceable reference devices.

- Adaptability – Suitable for use in cleanrooms, industrial plants, R&D labs, and even outdoor maintenance conditions.

Standards Governing Test Gauges

The credibility of a test gauge lies not just in its construction but in its compliance with recognized standards:

- ASME B40.100 (United States): Specifies pressure gauge design and accuracy standards.

- EN 837 (Europe): Governs bourdon-type gauge design accuracy and safety.

- ISO/IEC 17025: Defines the requirements labs must meet to use test gauges within a traceable calibration chain.

- BIS Standards (India): Ensure locally manufactured gauges meet national benchmarks.

For global operations, using gauges aligned with these standards ensures universal recognition of calibration results.

Test Gauge Manufacturing in India

Over the past decade, India has built a strong reputation as a provider of calibration instruments, including test gauges. The growing demand in pharmaceuticals, automotive, oil and gas, and power sectors has fueled domestic production.

Characteristics of Indian-made test gauges include:

- Diversity: From analog precision test gauges for labs to digital smart gauges for industrial calibration.

- Customization: Stainless-steel protection for corrosive environments, liquid-filled versions for vibration resistance, and compact portable designs for field checks.

- Affordability with Quality: Indian manufacturers offer precision at competitive costs compared to Western markets.

- Export Markets: Indian test gauges are increasingly popular in the Middle East, Africa, and parts of Europe.

Large industrial clusters in Pune, Bangalore, and Mumbai are leading in this growth, positioning India as a global competitor in precision instrumentation.

Calibration vs Accuracy Test Gauges

Attribute | Calibration Test Gauges | Accuracy Test Gauges |

Main Role | Used as reference standards in calibration labs | Used for quick spot-checks in the field |

Accuracy | ±0.1% to ±0.25% FS | ±0.25% to ±0.5% FS |

Environment | Controlled lab conditions, calibration benches | Real-world plant inspections, maintenance |

Use Frequency | Periodic reference benchmarking | Frequent routine verification |

This complementary relationship ensures systems remain both globally calibrated and locally reliable.

Industry Examples

- Pharmaceutical Manufacturing

Sterilizers and bioreactors depend on exact pressures to guarantee drug safety. If even one gauge is off, an entire batch can fail. Calibration test gauges guarantee that doesn’t happen. - Refineries

Oil and gas pipelines rely on accurate readings to avoid rupture. Pressure test gauges detect discrepancies early, preventing both accidents and environmental disasters. - Automotive

Hydraulic brake test rigs must deliver reliable data before vehicles roll off assembly lines. Test gauges are built into the quality verification process. - Research Facilities

Experiments on gases, fluids, or new materials require repeatable measurements. Test gauges confirm that instruments in use report true values. - Utilities

From nuclear to hydroelectric plants, precise measurements keep turbines and steam generators safe. Test gauges provide the assurance that operational readings align with reality.

Choosing the Right Test Gauge

For procurement managers and engineers, selecting the right gauge is a critical task. Key considerations include:

- Required Accuracy: Laboratories may demand ±0.1%; field sites may accept ±0.5%.

- Pressure Range: Select a gauge with a pressure span above routine operating conditions (by ~150–200%).

- Environment: For corrosive or vibration-prone areas, choose liquid-filled stainless-steel gauges.

- Standards Compliance: Always confirm traceability to ISO, ASME, or BIS standards.

- Manufacturer Reputation: Reputed suppliers provide calibration certificates and durable designs.

Conclusion

At its core, a test gauge is not just another measuring device—it is the cornerstone of measurement trust. By serving as the benchmark, it ensures that every other device measuring pressure or related parameters remains accurate, safe, and compliant with global standards.

Industries ranging from pharmaceuticals and aerospace to energy and automotive find themselves depending on test gauges for more than compliance. They rely on them for safety, for efficiency, for customer trust, and ultimately for credibility in global markets.

With the rise of test gauge manufacturers in India, organizations worldwide gain access to reliable, cost-effective instruments without compromise. As industries continue to embrace automation and stricter quality control, the role of precision, calibration, and accuracy test gauges will only become more vital.

FAQs

Q 1. What makes test gauges different from ordinary pressure gauges?

A. Test gauges are reference instruments built for calibration and accuracy verification, offering far tighter tolerances than standard operational gauges.

Q 2. How often should test gauges be recalibrated?

A. Typically once a year. However, critical sectors like aerospace or pharmaceuticals may recalibrate every six months.

Q 3. Do digital test gauges replace analog test gauges?

A. Not entirely. Digital gauges offer higher resolution and convenient data logging, but analog gauges remain irreplaceable in rugged, vibration-heavy industries.

Q 4. What accuracy levels are common?

A. Most calibration test gauges range from ±0.1% to ±0.25% FS, whereas accuracy test gauges range between ±0.25% and ±0.5%.

Q 5. Which industries rely most on calibration test gauges?

A. Pharmaceutical manufacturing, oil & gas, automotive, aerospace, power plants, and R&D labs form the largest user base worldwide.

Q 6. Are Indian test gauges globally recognized?

A. Yes, Indian manufacturers adhere to ISO, ASME, and BIS standards, and many products are exported internationally.