Moisture Kills Compressors! How a Moisture Separator Protects Them

The Hidden Enemy Inside Compressed Air

Compressed air systems have an unavoidable flaw: they generate water. On a standard 80°F (27°C) day with average humidity, a 100 HP compressor brings in enough atmospheric water vapor to produce nearly 18 gallons of liquid condensate per shift. If that water isn’t intercepted immediately, it travels downstream to rust out steel piping, wash away essential tool lubrication, and destroy pneumatic valve seals.

For plant managers and system designers, the “dryness” of the air at the intake doesn’t matter. What matters is the removal strategy after compression.

The Moisture Seperator is the first line of mechanical defense in this battle. Unlike complex air dryers that remove invisible vapor, a moisture separator tackles the bulk liquid—the heavy flood of water that overwhelms filters and ruins production cycles. Running a compressed air system without one is an open invitation to equipment failure.

What Is a Moisture Seperator in Compressed Air Systems?

A Moisture Seperator (often listed in parts catalogs as a Moisture Separator) is a vessel installed directly in the discharge piping of a compressor. It is a mechanical removal device designed to physically separate bulk liquids, oil aerosols, and solids from the air stream using inertia and gravity.

It is critical to understand the distinction: A moisture seperator removes liquid water; it does not lower the dew point.

In an air system schematic, the separator sits between the compressor (specifically the aftercooler) and the air treatment assembly (dryers and filters). It serves as the “roughing” filter, removing the largest volume of contaminants so that delicate downstream equipment can function properly.

How Moisture Forms Inside Air Compressor Systems

To fix the problem, you have to understand the physics creating it. Water in compressed air is not an accident; it is a direct result of thermodynamic laws.

- Concentration: A compressor takes a large volume of air—roughly 8 cubic feet of ambient air to make 1 cubic foot of compressed air at 100 PSI—and squeezes it. That compression process concentrates the invisible water vapor present in the atmosphere.

- Heat vs. Cooling: During compression, the air gets hot (often leaving the pump element above 200°F). Hot air can hold significant amounts of water vapor.

- The Dew Point Crash: As the air leaves the compressor and enters the distribution piping or the aftercooler, it cools rapidly. Cold air cannot hold as much vapor as hot air. The excess moisture has nowhere to go, so it changes phase from gas to liquid condensate.

This phase change typically happens right at the compressor outlet. If a compressed air moisture separator is not positioned here to catch the liquid immediately, that condensate is blown down the pipe at 100+ PSI.

How a Moisture Seperator Works (Step-by-Step)

The vast majority of industrial separators utilize “cyclonic” or “centrifugal” action. They have no moving parts inside the housing, which makes them durable and reliable if sized correctly.

- Directional Intake: Compressed air enters the housing through a directional vane or contoured inlet. This geometry forces the linear airflow into a high-velocity spiral.

- Centrifugal Force: As the air spins violently inside the housing, distinct g-forces are created. Water droplets, oil mist, and dirt are significantly denser than the air itself. The spin flings these heavy contaminants outward against the housing wall.

- Friction and Gravity: Once the water hits the metal wall, friction kills its velocity. The droplets combine into larger drops and slide down to the “sump” (the collection area at the bottom of the bowl) via gravity.

- The Vortex Finder: A specialized tube located in the center of the housing allows the dry air—which stays in the middle of the vortex due to lower density—to rise and exit the outlet port.

- Baffle Protection: Most units have a baffle near the bottom to ensure the turbulent air doesn’t dip into the sump and re-absorb (re-entrain) the dirty water already collected.

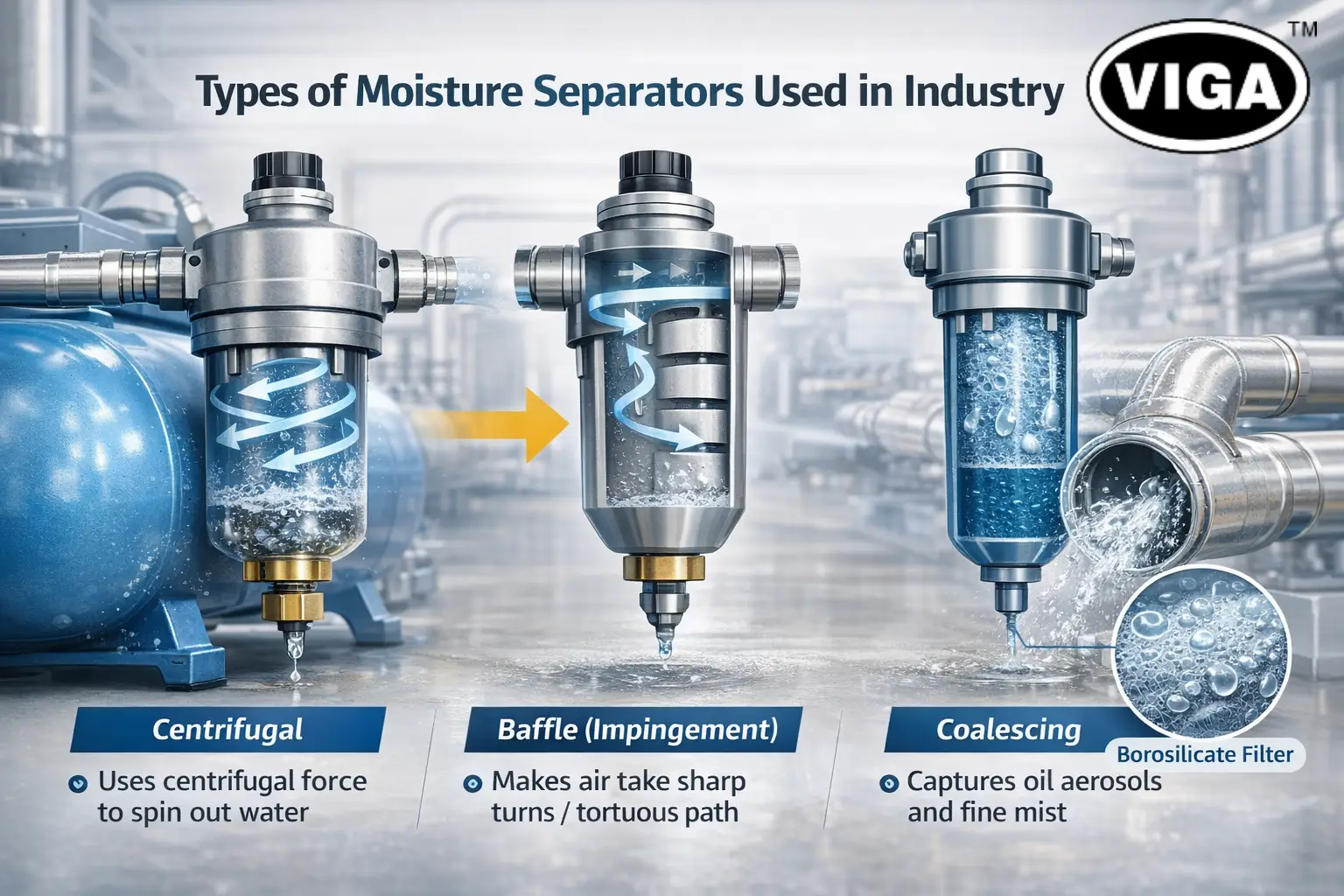

Types of Moisture Separators Used in Industry

Different flow rates and applications call for specific separation technologies.

1 Mechanical Moisture Separators

- Centrifugal Type: The standard design described above. It offers low pressure drop and high efficiency (removing 99% of bulk liquid) assuming steady airflow. It relies on velocity to create the “spin,” so correct sizing is non-negotiable.

- Baffle (Impingement) Type: These rely on a tortuous path rather than a spin. The air is forced to make sharp turns around internal plates. The water momentum carries it straight into the plate where it drains off. These are excellent for variable flow rates but often create a higher pressure drop (energy penalty) than centrifugal types.

2 Coalescing Moisture Separators

Strictly speaking, coalescers are filters, but they are often grouped into this category. They utilize a borosilicate glass matrix to capture oil aerosols and fine mists that mechanical separators miss.

- Engineering note: A coalescer creates a barrier. If hit with a slug of bulk water, a coalescing element will saturate, causing a massive pressure spike. It must always be installed downstream of a mechanical moisture seperator.

3 Moisture Seperator vs Air Dryer

These terms are not interchangeable.

- Moisture Seperator: Removes liquids. Leaves the air at 100% relative humidity.

- Air Dryer (Refrigerant/Desiccant): Removes vapor. Reduces relative humidity.

- A system needs both. A separator without a dryer creates “wet” air as soon as the pipe cools further. A dryer without a separator will flood and fail.

Why Moisture Is Dangerous for Compressors & Pneumatic Equipment

Condensate in the lines is more than just water; it is often an acidic slurry of water, atmospheric hydrocarbons, and compressor oils. This mixture is aggressive.

- Pneumatic Automation Failure: High-speed solenoids and actuators rely on factory-applied grease. Water washes this grease away. The result is “stick-slip” friction, causing valves to jam and cylinders to seize.

- Corrosion Scale: Iron and steel piping corrodes rapidly in the presence of warm, oxygen-rich water. This rust eventually flakes off, traveling downstream to clog fine orifices and blast nozzles.

- End-Product Spoilage: In spray painting, a single droplet of oil/water creates “fisheye” craters. In food packaging, it contaminates the sanitary environment.

- Freezing: In outdoor facilities, accumulated condensate freezes in winter. This blocks flow and can burst expensive rigid piping or housing bowls.

Benefits of Installing a Moisture Seperator

The ROI on a moisture seperator is usually immediate, given the low hardware cost relative to the protection provided.

- Dryer Protection: Refrigerated air dryers function by cooling air to condense vapor. If the incoming air is already carrying gallons of warm water, the dryer’s heat exchanger is overwhelmed. A separator removes that thermal load, allowing the dryer to run efficiently.

- Reduced Pressure Drop: Water accumulation effectively reduces the inner diameter of pipe distribution networks. Keeping pipes dry maintains proper flow dynamics and system pressure.

- Reduced Maintenance Costs: Manually draining receiver tanks and replacing rusted pneumatic tools costs labor hours. Automatic separation automates the removal process.

Where to Install a Moisture Seperator in a Compressor System

Installation location dictates performance. Placing it in the wrong spot renders it useless.

After the Aftercooler

This is the primary location. The aftercooler chills the hot compressed air, forcing the moisture to condense into droplets. The Moisture Seperator should be placed immediately downstream to catch this fresh condensate before it enters the main distribution header.

Before Air Receivers

Installing before the tank (“wet tank” configuration) keeps the bulk of the corrosive sludge out of the receiver vessel. This extends the certification life of the pressure vessel.

Before Air Dryers

Pre-filtration is mandatory for air dryers. A separator prevents liquid “slugs” from fouling the dryer heat exchangers (refrigerated) or ruining the desiccant beads (adsorption dryers).

Point-of-Use

Long piping runs often allow air to cool below the initial dew point, forming new condensate. A small separator installed at the drop-leg of a machine protects that specific tool.

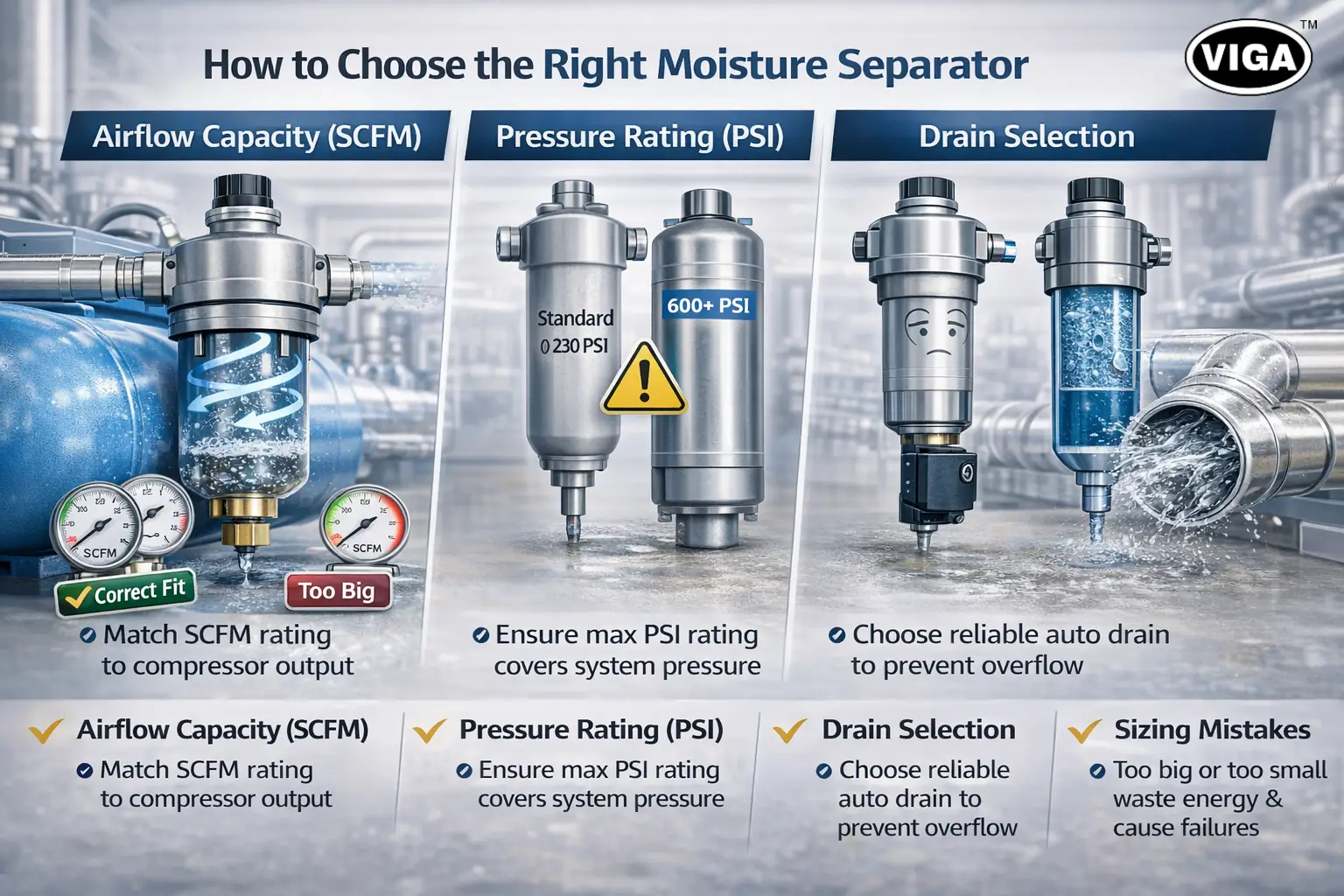

How to Choose the Right Moisture Separator

Buying based on pipe connection size (e.g., “I need a 2-inch separator”) is the most common mistake in system design. Sizing relies on flow dynamics, not thread size.

- Airflow Capacity (SCFM): Centrifugal separators rely on a specific velocity range to create the vortex.

- Oversized: If you put a 500 CFM separator on a 50 CFM compressor, the air won’t spin fast enough to throw the water out. The water will just float through.

- Undersized: The restriction creates a high pressure drop, wasting energy, and the high velocity may re-entrain the water.

- Rule: Match the separator’s flow rating to the compressor’s output, regardless of pipe size.

- Pressure Rating: Standard housing usually covers up to 200 or 230 PSI. High-pressure boosters or blow-molding applications require rated vessels (600+ PSI).

- Drain Selection: The separator acts as a bucket. If the bucket has no hole, it fills up.

- Automatic Float Drain: The standard solution. Opens when water lifts the float.

- Zero-Loss Drain: The premium solution. Uses sensors to open only when liquid is present, preventing the loss of compressed air.

Common Moisture Separator Problems & Troubleshooting

If water is still appearing downstream despite having a separator, check these issues:

- The “Milkshake” Clog

In oil-injected screw compressors, condensate mixes with oil to form a thick, white emulsion. This sludge clogs standard float drains rapidly. If the drain clogs, the separator bowl fills with liquid. Once full, the air passes right through the water, carrying it downstream.

- Fix: Clean the bowl and verify the drain mechanism is rated for oil-contaminated condensate.

- Flow Mismatch

If a plant increases air demand or upgrades compressors but keeps old separators, flow velocity might be too high, carrying water droplets past the separation vortex (carryover). - Installation Direction

Most housings have a flow arrow. Installing a separator backward negates the internal aerodynamic design, reducing efficiency to near zero.

Maintenance Tips for Maximum Moisture Removal Efficiency

A Moisture Seperator is a static device, but it requires inspection.

- Weekly Drain Check: Press the test button on electric drains or visually confirm water discharge on float drains. A separator with a failed drain is just a section of pipe.

- Annual Cleaning: Disassemble the housing. Wipe the internal vanes or spinner. Heavy sludge buildup on the spinner changes the aerodynamics and reduces separation efficiency.

- O-Ring Replacement: When reassembling, replace the housing seal to prevent expensive air leaks.

Moisture Separator vs Moisture Trap vs Air Dryer

The terminology often confuses buyers. Here is the breakdown:

Device | Primary Function | State of Water Removed | Position in System |

Moisture Seperator | Bulk removal via centrifugal force | Liquid (Droplets) | After Compressor / Point of Use |

Moisture Trap | Basic collection via gravity | Liquid (Trace amounts) | End of pipe runs / Regulators |

Air Dryer | Dew point suppression | Vapor (Humidity) | Downstream of wet tank |

Summary: A separator is a heavy-duty bucket. A trap is a small cup. A dryer is a dehumidifier. Industrial systems require a Separator and a Dryer.

Industrial Applications That Require Moisture Seperators

While every system needs them, these sectors have zero tolerance for failure:

- Food & Beverage: Water breeds bacteria. Point-of-use separation (followed by sterile filtration) is a safety compliance issue.

- Automotive Paint: “Fish-eyes” and blistering caused by moisture droplets require expensive rework and sanding.

- Sandblasting: Wet air causes abrasive media to clump (pack out) in the hopper, stopping work immediately.

- Pharmaceutical: Pill coating and powder conveying rely on perfectly dry air to prevent the product from turning into a paste inside the machine.

FAQs

Q1. What does a moisture separator do?

It mechanically removes bulk liquid condensate and particulates from the airstream using centrifugal force, draining the fluid before it can enter the plant piping.

Q2. Is a moisture separator enough for compressors?

No. It removes liquid water but leaves water vapor. As air travels and cools, more liquid will form. To stop condensation completely, you must add an air dryer.

Q3. How often should it be drained?

The sump should never be allowed to fill completely. Automatic drains (float or electronic) are highly recommended to ensure it drains continuously as water accumulates.

Q4. Can moisture damage pneumatic valves?

Yes. Water strips lubricant, causes rust, and leads to valve spool seizure (sticking), causing machine downtime.

Q5. Where should it be installed?

The most critical location is immediately downstream of the compressor’s aftercooler. Secondary units should be installed before air dryers and at point-of-use drops.

Conclusion: Dry Air Is the Foundation of a Healthy Compressor System

There is no way to bypass physics: compressing air generates water. The difference between a reliable production line and a maintenance headache is how that water is managed.

A properly sized Moisture Seperator acts as the shield for the entire system. It protects the expensive air dryer from overloading, it prevents filter saturation, and it stops the bulk flow of corrosive liquid into the factory piping. Whether upgrading an existing loop or designing a new compressor room, verify that the moisture separator is correctly rated for the airflow and outfitted with a reliable drain. It is a small investment that prevents massive failure.