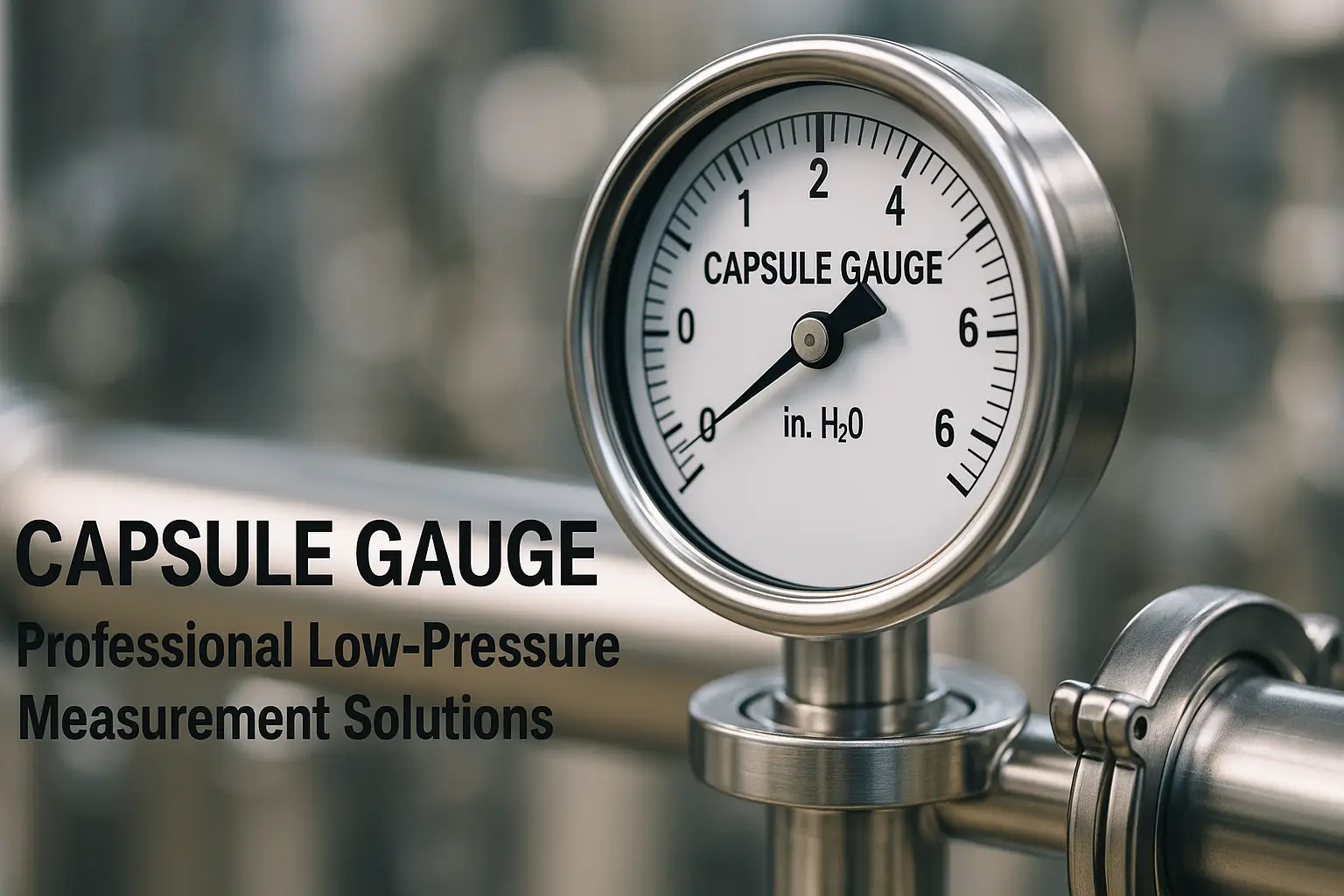

Capsule Gauges: Professional Low-Pressure Measurement Solutions

When precise low-pressure measurements are required, capsule gauges are the most reliable option. Standard gauge technology often fails below 1 bar (roughly 15 PSIG) because most common designs are optimized for higher pressures. Bourdon tubes, for example, suffer diminishing accuracy at the low end of their range. Their ability to track rapid changes declines, hysteresis errors increase, and parallax errors exacerbate the disparity between the pointer and actual pressure. When the low side of their characteristic curve coincides with the pressure application of interest, the measurement becomes irrelevant and engineers are effectively measuring noise instead of the signal.

This accuracy shortfall is not an abstract nuisance; it translates to significant risks and inefficiencies in critical applications. Low-pressure monitoring is the unsung backbone of performance assurance in complex HVAC system controls, leak testing of gas distribution lines, and the maintenance of cleanrooms in pharmaceutical manufacturing, among many other processes. Compliance with regulatory and internal audits, safety of personnel, and the integrity of manufactured products all rely on reliable low-pressure data. When the instrument fails to provide that data, the alternative is often unsafe guessing, which in turn leads to costly and potentially damaging corrective actions.

This is where capsule pressure gauges assert their distinct value. They are not simply alternative pressure-measuring devices; rather, their conception is rooted in the need for reliable performance within the low-pressure regime. Capitalising on engineered high sensitivity, capsule gauges detect and display pressure variations on the order of a few pascals, variations that Bourdon or diaphragm gauges of the high-pressure class routinely overlook. The ensuing discussion illustrates the operating principle of the capsule, articulates its comparative advantages, and rationalises its preferred use in low-pressure applications.

The Operative Principle: The Capsule Diaphragm in Motion

At its most fundamental, the architecture of a capsule gauge is straightforward:

a sealed metallic capsule deforms in a discretely elastic manner. The analogy to the Bourdon’s rigid C-section is misleading. Envision instead a pair of thin, corrugated, circular metal diaphragms, each resembling a refined and miniaturised cymbal. Following precise fusion or brazing the circumferences of the disks form a sealed, elastic chamber, the capsule that acts as the responsive “lung” of the instrument.

The process of pressure measurement within the capsule gauge unfolds as follows:

first, the instrument admits low-pressure gas or air to the interior of the sealed chamber.

The capsule enlarges: When external pressure increases, the sealed capsule distends, a phenomenon akin to the inflation of the thoracic tissue. While the absolute increment in diameter seldom exceeds a few tenths of a millimeter, the displacement is remarkably consistent over the entire working range.

The motion is magnified: This minuscule excursion is mechanically leveraged by a nested train of rigid steel levers, micron-toleranced gears, and ultra-low-friction bearings. Each link multiplies the displacement by a factor of 15 to 25, translating the capsule’s microscopic deformation into a macroscopic sweep in the indicator.

The reading is definite: The scaled motion transmits a uniform angular displacement to the index needle, which traverses the scored dial with uninterrupted rhythm. Therefore, subtle changes in pressure are rendered as discrete and reproducible graduations, eliminating human interpretation error and ensuring traceability in calibrated units.

The wavy patterns, or micro-corrugations, embossed on the diaphragm of the pressure capsule serve a critical engineering function. They are not ornamental; by providing a tuned elasticity, they permit the capsule to alternate between its maximum and minimum volume indefinitely without permanent deformation, all while resisting accidental bulging in the otherwise symmetric shape. Equally critical is the selection of the diaphragm material. For the great majority of laboratory and field applications, 316L stainless steel is the preferred option; its relatively low reactivity, excellent tensile strength, and immune behaviour to ordinary corrosives ensure long service. In applications featuring chemical aggressiveness, elevated temperature, or both, high-performance alloys—specifically Hastelloy and Inconel—are warranted even though their lower elongation can impose tighter diameter tolerances.

Domains of Application: Capsule Gauges in Context

Capsule gauges are preeminent in the measurement of low differential pressures in sectors where minute filament pressures are a performance driver. The contemporary HVAC system is, in effect, a self-regulating biome that depends upon a finely judged differential to synchronize fluid horsepower with thermal demand.

Duct static pressure is the most frequently monitored variable: the capsule gauge thereby verifies that the fan motor is running at its design duty while nuclearizing the risk of energy gradient, or entropy, losses attributable to excessive acceleration against internal fouling. The separation of the gauge in the airstream allows for an unprecedented real-time cross-tab of fan behaviour against projected air path resistance.

Monitoring Differential Pressure Across Filters: By quantifying the change in pressure measured immediately upstream and downstream of a filter, facility engineers obtain an unambiguous indicator of filter condition, eliminating inefficient replacements dictated solely by predetermined intervals. Maintenance cycles may therefore be extended or accelerated without the waste and expense of a blanket schedule.

Room Pressurization for Containment Environments: Maintaining a precise pressure differential is a critical barrier for facilities that process or analyze potentially hazardous agents. For clinical, pharmaceutical, and research environments, even a differential of a few Pascals—typically between one-tenth and one-twentieth of an inch water column—constitutes a vital control. Portable capsule gauges, whose resolution is the same order of magnitude as the differential, provide the only rapid, in-situ verification of the minute pressure boundaries that safeguard sterile zones from contamination.

For laboratory instrumentation, exact control of low pressure and vacuum is equally vital. Many analytical and process instruments require steady low pressure to obtain valid analytical responses or to ensure that process variables track designed parameters.

Manufacturing and containment of therapeutics rely on capsule gauges to verify the enclosure of biological containment chambers and the integrity of biocontainment suites. By maintaining a negative differential pressure, both personnel and product are protected from the ingress of biological agents, while regulatory bodies, such as the FDA and EMA, demand validated, datalogged evidence that these pressure levels are sustained. Capsule gauges deliver that assurance by supplying time-stamped, quantifiable pressure data that is immune to the drift or inaccuracy that may otherwise jeopardize compliance.

Analytical Instruments: Mass spectrometers and scanning electron microscopes require a rigorously stable vacuum for optimal performance and safety, making monitoring a critical step in experimental protocols. Capsule gauges, configured for monitoring both the rough and medium vacuum segments, serve as the protective interface, continuously scanning for deviations that could indicate an impending breach.

Certain experimental workflows operate just a nominal distance from atmospheric pressure, and corresponding measurement is referred to as compound pressure. Capsule gauges can be manufactured as compound devices: a single dial indicates both vacuum and vacuum-pressure domains. This design circumvents the operational limitations typically encountered when attempting to use standard Bourdon tubes in similar situations.

In applications handling flammable scenarios, the threshold for risk is often measured in cubic centimeters a minute; therefore, pristine seals and vigilant monitoring protocols are mandatory. A insufficient seal in the proximity of gases such as propane or methane can solidify into an ignition threshold the moment operational temperatures align.

Low-Pressure Gas Lines: Residential and commercial distribution networks generally operate at sub-5 PSI pressures. Capsule gauges are ideally suited to these systems, combining unobtrusive installation with a mirrored dial that reflects nominal line pressures while retaining readability.

Leak Detection: The high sensitivity of capsule gauges enables operators to perennial decant observations of pressure level, pinpointing decelerations that are proof of micro-hole flows. Fixed algebraic Citrix of operating pressures motif, this advance mechanism directs the maintenance crew to a predictable location, permitting the execution of intervention measures well in advance of an original.

Biogas and Other Fuels: In environments where corrosive gases exist at low pressure, robust and corrosion-resistant pressure monitoring becomes crucial. A capsule gauge constructed entirely from stainless steel will withstand such atmospheres while ensuring leak-tight integrity and monotonic reading stability.

The Head-to-Head: Capsule Gauge versus Bourdon Tube

The question centers on application, not a sweeping judgment of superiority. Each instrument is engineered for a specific pressure spectrum and chemical milieu. The capsule gauge is therapeutically precise at low and differential pressures; the Bourdon tube leverages greater mechanical leverage for higher pressures. Choosing the instrument is tantamount to selecting a scalpel when a torque wrench would introduce mechanical risk.

Capsule Gauge Feature Comparison with a Bourdon Tube

Operating Pressure Range –

- Very Low (typically less than 1 bar/15 psi)

- Medium to Very High (greater than 1 bar/15 psi)

Performance across Low Pressure –

- Accuracy is commendable (±0.5% to ±1.5% of full scale)

- Accuracy is poor, prone to large error

Responsiveness –

- High sensitivity, detects minor pressure variations

- Low sensitivity, large pressure input required to actuate

Response Temporal Characteristic –

- Fast, typically 1 to 2 seconds

- Moderate, 5 to 10 seconds

Mechanical Rigidity –

- Robust with potential enhancement via filling liquids

- Superior, inherent resistance to mechanical deformation

Construction –

- elicate precision capsule mechanism

- Sturdy, helically deformed C-shape element

Application Suitability –

- HVAC, gaseous lines, controlled lab environments, vacuum systems

- Hydraulic, compressor, and high-pressure systems

Selection and Lifetime Maintenance – Simple process if minor operational and environmental details are controlled, ensuring expected product longevity.

Locate the Optimal Pressure Band: To maximize accuracy and longevity, select a dial range such that the process pressure consistently lies between 50% and 75% of full scale. Readings that etch the needle against the upper stop or hover at the pivot’s lower end can generate significant deviations and consequently drive premature failure of the instrument.

Evaluate the Service Environment: Identify and document the extremes that the gauge will encounter: elevated or sub-zero temperatures, sinusoidal accelerations, or persistent exposure to corrosive vapours. If the application warrants, request an operating device with built-in thermal compensation, a dampening liquid fill, or corrosive-resistant materials for both the case and the wetted components.

Confirm Chemical Compatibility: Validate that every wetted part in contact with the process fluid is chemically acceptable for biogas, chemical, or similar applications. Failure to verify this step can quickly invalidate the measurement and damage the sensor.

Handle with Caution: The pressure-sensing system of a capsule gauge is delicate; shock loading or excessive vibration can deform the measuring element. Avoid any mounting site subjected to dynamic forces and handle the device securely to prevent mechanical damage.

Prevent Overpressure: The leading cause of fatal pressure capsule failure is downstream overpressure. A transient pressure spike exceeding the capsule limit results not merely in director fatigue but in a permanent morphological change in the sensing bellows which compromises long-term sensitivity. Always install burst disks, pressure-limiting valves, or rupture membranes in the fluid path wherever pressure excursions cannot be guaranteed to remain within the manufacturer’s specifications.

Calibrate Judiciously: For critical service, an initial annual calibration is prudent practice, serving both to document stability and to trend any systematic error. Once the gauge proves stable for an entire calibration cycle, periodicity may be safely extended to a biennial or triennial frequency, dependent on service conditions. Agenda-based calibrations fulfill the role of ongoing validation and, more succinctly, of continuous process monitor.

In summary:

The appropriate gauge for the challenge. Capsule pressure devices uniquely fill the gap between ultra-high-accuracy instruments and batch-sensitive, process-grade transmitters, achieving verified precision in the sub-atmospheric, sub-0.3MPa range. The gauges’ robust analog mechanics operate independent of any auxiliary energy supply, introducing zero drift beyond elastic recovery error, and serving both technician and process with a self-explanatory, moment-to-moment assurance of operational confidence.

Engineered quietly yet relentlessly, these instruments are indispensable allies in promoting safety and operational efficiency, preserving the integrity of critical pharmaceuticals and optimizing the energy profiles of our constructions. A thorough understanding of their principles and integration points enables informed design decisions, ensuring the appropriate unit is deployed under the most demanding conditions, with only minimal margin for error.

Frequently Asked Questions

Q 1. What is the realistic accuracy specification for a capsule gauge?

A. When sourced through industrial procurement, capsule gauges typically exhibit accuracy within the range of ±1.0% to ±1.6% of full scale. Should experimental validation deem a superior specification requisite, laboratory-grade gauges that possess enhanced construction may achieve a precision of ±0.5% or better. Accuracy is maximized when the measurement occurs within the mid-range of the instrument scale.

Q 2. How do temperature variations and mechanical vibration influence the measurements of a capsule gauge?

A. Thermal variations and mechanical vibration exert quantifiable influence. The operational diaphragm, characterized by a relatively extensive surface area, may transduce temperature fluctuations into dimensional alterations, thereby distorting the indicia. Consequently, select instruments incorporate on-board temperature compensation systems. A hydraulic filling employed within the case serves to damp mechanical oscillations, thereby stabilizing the pointer and preserving measurement fidelity in the presence of severe vibrational loading.

Q 3. At what frequency should these gauges be calibrated?

A. Calibration frequency should directly correlate with the criticality of the application. In the context of a pharmaceutical cleanroom, guideline compliance is non-negotiable, necessitating annual calibration. Conversely, a less critical duct pressure gauge may extend to 24 or even 36 months, provided the initial year demonstrated consistent accuracy. After that, less frequent checks may still be defensible, though documenting the long-term drift remains prudent.

Q 4. Under what circumstances is a capsule gauge preferable to a contemporary electronic pressure transmitter?

A. The capsule gauge excels when conditions demand an uncomplicated, highly readable, battery-independent local display. Its construction is durable and straightforward for installation. In contrast, an electronic transmitter becomes indispensable when the application requires interfacing with a central logic controller (PLC or DCS), achieving a resolution beyond the capsule’s capacity, or logging pressure data remotely. It is a matter of solving different technical objectives rather than outperforming one another.

Q 5. In which manner do users typically compromise a capsule-type pressure gauge in circumstances of unintended misuse?

A. Excessive pressure is by far the predominant cause. Subject to an instantaneous over-pressure event—such as applying 100 PSI to a gauge designed to scale only to 10 PSI—the delicate capsule distorts permanently, leading to inaccurate readings. To safeguard functionality, prior to installing a capsule gauge, the user must establish the upper limit of the process system, select a gauge whose calibrated span accommodates that limit, and, where necessary, install an appropriate pressure protection device or diaphgram.