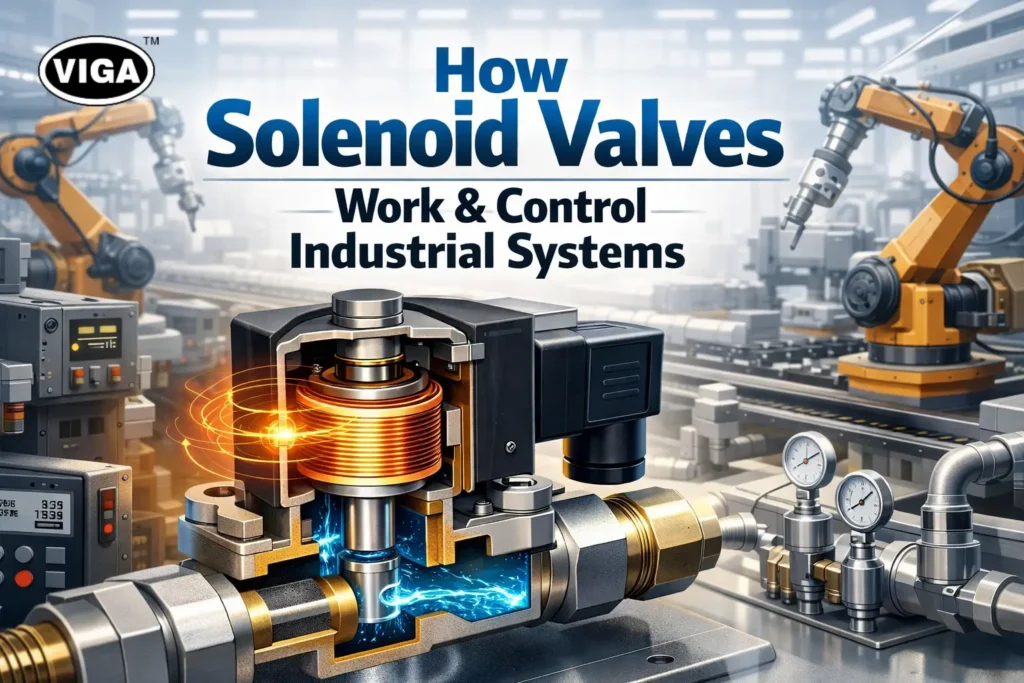

How Solenoid Valves Work & Control Industrial Systems

One Tiny Coil That Controls the Whole System — Inside the World of Solenoid Valves!

The Power of a Tiny Coil

The efficiency of every modern factory, laboratory, and mechanized facility stands or falls based on one often-overlooked, small piece of hardware: the Solenoid Valve. Look, the reality is simple. As control systems professionals, install a vast, intricate automation architecture—network protocols, advanced PLCs, sophisticated sensor packages—and what brings all that expensive logic down? Usually, a three-inch component. By faithfully and reliably standing as the precise point where electrical thought instantly translates into powerful mechanical force.

See the stories about entire automotive final assembly lines coming to a screeching, emergency halt, only to find the root cause was one tiny coil on an upstream cylinder’s air valve that decided to stop taking current. The economic loss of that stoppage makes the choice of the correct component paramount, underscoring its foundational role in all Industrial Automation. This small device is far more than an on/off switch; it’s the high-speed flow control valve that governs literally everything that moves, making it indispensable for system reliability and performance. Getting its application wrong means you’ve built your highly tuned race car on square tires.

What Is a Solenoid Valve?

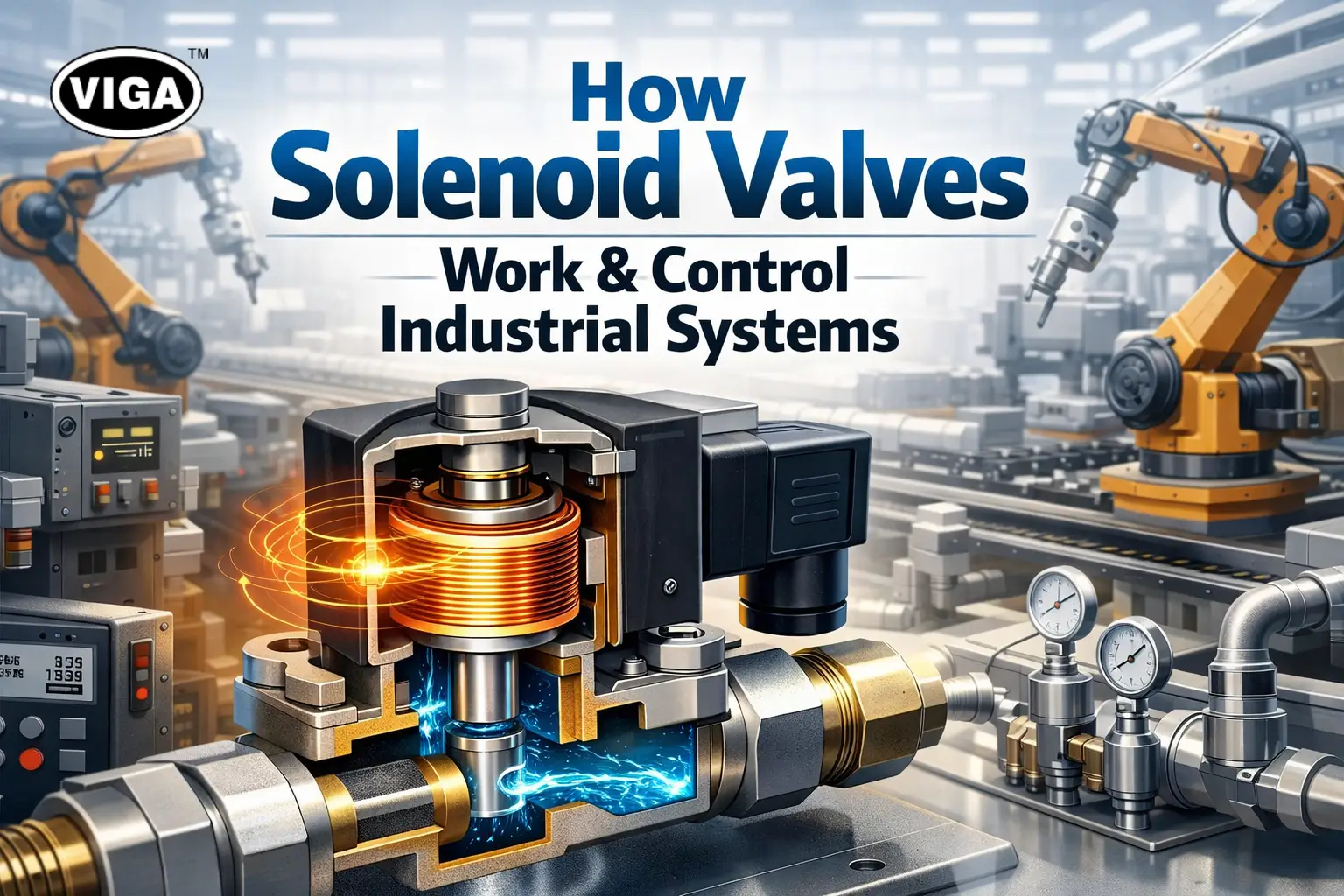

So, what is a solenoid valve, at its core? It’s the ultimate electro-mechanical actuator, designed for rapid, remote control over the flow of any type of media. In plain terms, it uses the science of magnetism to operate a physical plug (a seal or diaphragm) that allows fluid, air, or gas to flow through a specific line.

To simplify the expertise: Think of a solenoid valve as an intelligent gatekeeper, controlled entirely by a weak electrical pulse. This is an absolutely crucial component within any fluid control systems, where we’re managing materials that might be hazardous, expensive, or under extreme pressure. Two main parts in any good solenoid assembly, establishing its nature as an electromagnetic valve:

- The Coil (The Logic): This is the core. It is the tightly wound magnet wire. It receives its digital command (typically from 12VDC to 240VAC). This coil, when energized, immediately converts electrical current into usable magnetic force.

- The Valve Body (The Actuator): This is the metal or composite structure containing all the hydraulic bits: the fixed ports, the sealing orifice, the spring, and the internal ferromagnetic steel rod known as the plunger or armature.

In pneumatic systems, solenoids handle high-pressure air used to operate actuators; conversely, they are used for simple on/off commands on a municipal water line. That universality, allowing one design principle to cover everything, is its main engineering strength.

How a Solenoid Valve Works

The key to mastering this hardware lies in fully grasping the simple physics driving the solenoid valve working principle. The objective is to produce enough electromagnetic force to swiftly defeat the combined hydraulic pressure and the spring’s stiffness—all without a huge power draw.

Let’s trace the power flow in a standard Normally Closed (NC) valve configuration. This should provide the solenoid valve coil working explained clarity you need:

- Resting State: Without power, the engineered return spring is actively pushing the plunger downwards, keeping the durable seal tightly compressed onto the flow orifice. The hydraulic force of the media line is also working in the same direction, further securing the closed seal. Flow is firmly blocked.

- Electrical Activation: The PLC sends an “open” signal. The solenoid valve coil immediately receives its specific operating current.

- Magnetic Field Genesis: Instantly, current flow transforms the coil into a temporary electromagnet. The goal isn’t gentle power—the solenoid must rapidly develop a powerful magnetic pull concentrated on the center of the coil’s core.

- The Plunger Movement: This immense magnetic pull vertically overcomes the tension of the return spring (which is quite strong) and simultaneously defeats the internal hydraulic pressure. The plunger is pulled forcefully upwards, a purely physical translation of energy.

- The Flow Open Process: As the plunger ascends, it pulls the sealing mechanism away from the valve seat, clearing the path. Media immediately flows from the input to the output. This is precisely how solenoid valves control flow at its critical juncture.

- Deactivation (Close Command): The electrical current is instantly removed. The magnetic field immediately and entirely collapses. Without that counteracting magnetic force, the dedicated return spring immediately snaps the plunger back down, seating the seal perfectly and restoring the flow barrier.

The near-zero latency of this operation makes it perfect for fast-action valve actuation.

Why Solenoid Valves Are the Backbone of Automation

In the running automated processes, the speed, precision, and simplicity that solenoids offer have no effective parallel for basic binary (on/off) media control. Without them, Industrial Automation it would grind to a clumsy halt.

- Exceptional Response Time: The best solenoid valve units are built to shift and seal in under 20-30 milliseconds. Compare that to the two-second operation time of a standard pneumatic actuator moving a larger butterfly valve! That high-speed sequencing capability is fundamental to keeping high-output machinery running effectively.

- Simple Remote Control Interface: A great strength of the solenoid valve in automation is its easy interface. Your sophisticated $100,000 process controller can reliably command thousands of individual, low-voltage solenoid valves using simple digital output cards. This makes distributed, large-scale flow control management highly affordable.

The Crucial Safety Interlock: This is a safety factor. NC Solenoid Valves provide the simplest and most cost-effective fail-safe condition possible: no power equals no flow. Linking these devices directly to an emergency stop or safety circuit ensures that if all power is dropped, hazardous motion, pressure, or chemical supply lines are automatically cut. This adherence to high standards for safety risks makes them preferred process control valves across many applications.

Types of Solenoid Valves Explained Clearly

There is no one “right” solenoid—only the right type for the application. The selection requires matching the application’s demand (failure state and flow dynamics) to the valve’s physical capabilities. Knowing the difference here saves both time and major capital investment.

Core Classification: The Failure State

Choosing between the two fundamental options dictates how your entire system behaves in a power failure.

Type of Valve | De-Energized Status (Default State) | Expert Tip/Use-Case Priority |

Normally Closed (NC) | Physically Closed: No flow, firmly sealed. | Mandatory when a controlled shut-off upon power failure prevents product loss or is safer (e.g., closing fuel lines, isolating power cylinders). |

Normally Open (NO) | Physically Open: Flow is permitted through the line. | Critical only when continuous operation, despite power failure, is required for system integrity or safety (e.g., venting a crucial vessel, essential cooling circuits). |

The difference between normally open and normally closed solenoid valves is a design decision based solely on your fail-safe analysis.

Actuation Type (How the Plunger is Moved)

- Direct Acting: As the name implies, the powerful magnetic field directly pulls the plunger to shift the seal. They are superb for instant action and zero-differential pressure (like emptying a non-pressurized tank), but they are limited to handling lower pressure loads and smaller port sizes due to magnetic strength limitations.

- Pilot-Operated (Indirect Acting): Used for sheer scale. They utilize the magnetic pull only to shift a small internal pilot hole, which then uses the high line pressure itself to push a much larger diaphragm, opening the main, large-volume port. They provide a massive leverage increase but absolutely require a minimum pressure differential to operate successfully—a common solenoid valve problems cause for new users.

Way and Port Arrangements

- 2-Way Valves: The basic ON/OFF switch. Two ports, one line. Used for simple starts, stops, and shutoffs for simple media flow control.

- 3-Way Valves: Three ports, designed to perform a dual function—like applying pressure to one port while simultaneously exhausting pressure from another. An example is the classic solenoid valve in pneumatic systems controlling a spring-return cylinder (single acting).

- 5-Way Valves: These are specialized, complex flow routers and the heart of fast, double-acting systems in pneumatic automation. They provide two independent control outlets and two independent exhaust paths, ensuring the dual motion of the actuator is fully managed at maximum speed. This is non-negotiable for synchronized movement in a robot or clamping press.

Applications of Solenoid Valves Across Industries

I’ve specified and repaired industrial solenoid valves across the board, from brewery cleaning lines to explosion-proof environments on oil rigs. Their pervasive solenoid valve applications prove their immense utility for solenoid valve for air and fluid control.

- Heavy Duty Manufacturing: Any pneumatic automation line is covered in solenoid valve manifolds—the flow to almost every moving piston, gripper, clamp, or emergency brake relies on milliseconds-perfect control of air through a valve body.

- Fluid & Chemical Processing: Essential for all systems managing flow control in pipelines. Specialized seals and materials are used to ensure proper media compatibility when managing everything from chilled water in HVAC to highly corrosive agents in etching or blending plants.

- Refrigeration Circuits: Used to instantly divert or inject refrigerant into different zones of a multi-stage cooler, optimizing heat exchange and system capacity for energy efficiency improvement.

- Oil & Gas Pipeline Control: Smaller solenoids are used for accurate, small-volume sample-taking, and in the critical fire-suppression and fuel-dump systems where immediate valve actuation on a pilot line controls a larger block valve—prioritizing fast safety interlocks.

- Food and Beverage Dosing: Used in aseptic and clean-in-place (CIP) protocols. Fast-acting solenoids precisely meter costly ingredients, syrups, and washing chemicals to guarantee high batch-to-batch product consistency.

What Happens When a Solenoid Valve Failure?

The solenoid valve failure is never just about replacing the valve itself—it’s about the unexpected hours of lost production and complex diagnostics required. Don’t be fooled by the simplicity of the part; a small component can cause colossal issues.

Here are the harsh realities of common solenoid valve problems and solutions from real job sites:

Symptom / Field Observation | The True Root Cause (What to Check First) | Impact and Your Immediate Resolution |

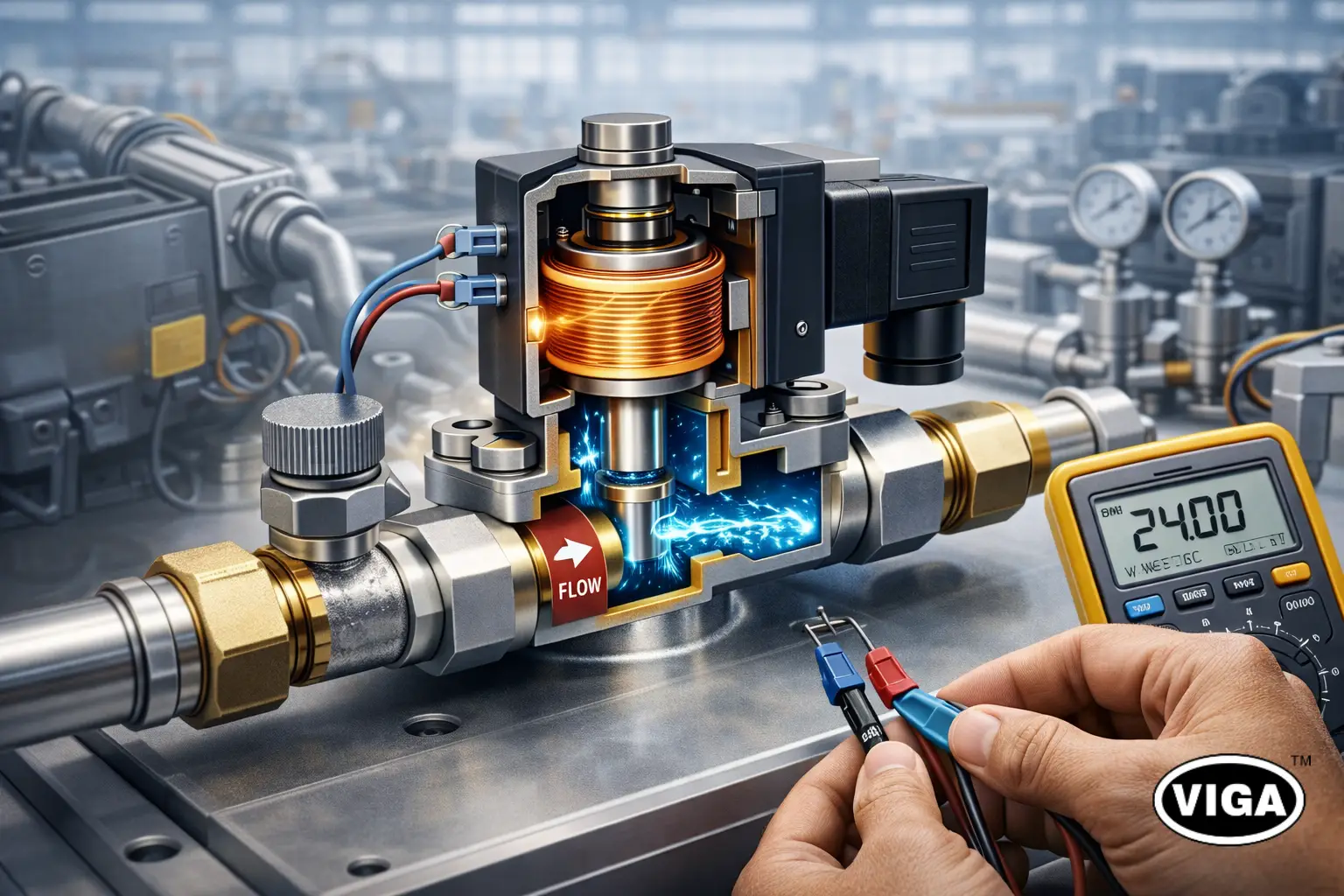

Valve Fails to Open or ‘Buzzes’ (No full seal) | Coil’s magnetic pull is too weak, often caused by a voltage sag (power dip) under load, or mechanical sticking of the plunger due to fine dirt contamination. | Leads to incomplete cycling. Test input voltage while actuating. The system can enter a permanent flow blockage state. |

Visible Coil Overheating (Smoking, melting epoxy) | Applying the wrong voltage or waveform (a classic solenoid valve failure causes problem), or a poor thermal path due to an overtightened electrical connector leading to premature breakdown of the windings. | Immediate safety risk. Leads to a high current draw and instant failure of the valve’s control; disconnect power and replace. |

Persistent Internal Leak (Hissing/Seeping) | Contaminants (scale, rust, threading sealant debris) embedded on the main valve seal, preventing a clean, 100% seal closure. | Major loss of costly media (pressure loss / air waste), disrupting pneumatic timing. Valve must be depressurized, disassembled, and the internals cleaned/polished. |

Sluggish or Delayed Valve Action | Friction build-up. Varnish or residue on the inner wall of the solenoid core tube impeding the speed of the plunger movement. | Affects the overall throughput and speed of the automation line. Clean the inner tube of the solenoid housing thoroughly using an appropriate solvent. |

A preventative approach means eliminating all external environmental factors (wrong pressure, voltage, temperature) that might prematurely trip these failure mechanisms.

How to Choose the Right Solenoid Valve

Selecting the right valve involves more complex homework than people usually think. How to choose the right solenoid valve means balancing chemical science, fluid dynamics, and electrical requirements—it is rarely a “take the largest size” exercise.

- Media Compatibility First, Always: Before pipe size, before price—confirm that the fluid/gas media is 100% chemically compatible with the specified valve seal material. An acid will quickly dissolve NBR (a common seal), and hot water rapidly degrades standard synthetic rubber. Match the temperature range, too. The Best Solenoid Valve is always the one chemically compatible.

- Sizing and Flow Rate: Never guess your pressure or flow requirements. Use the flow coefficient (Cv or Kv) specified by the manufacturer. Oversizing the valve for a low-flow line makes it clunky; undersizing leads to velocity issues and upstream system stress. Pay very close attention to whether it’s a “Zero Pressure Differential” (Direct Acting) or Pilot-Operated requirement.

- Coil Electrical Characteristics: AC or DC? What specific voltage (24VDC or 110VAC)? Match this to your power output perfectly, as a misstep can lead to immediate overheating and coil death. Modern industrial controllers often favor low-wattage DC coils for high-density manifolds, which are more energy-efficient and easier to manage with network power cards.

- The Environment Rating: Are you putting this valve outdoors or where wash-downs occur? Ensure the coil and connector are correctly IP-rated (e.g., IP65 or IP67 for water spray). If there’s an explosive hazard present (dust or gas), you legally must use an appropriately certified (Ex-Rated) solenoid enclosure to protect against disastrous spark creation.

Installation Best Practices

Getting the solenoid valve installation perfect is the first line of defense against almost all wear failures. These steps come from watching failures occur on the line, year after year.

- Filter and Regulate: The greatest disservice you can do a valve is give it unfiltered, raw system fluid. An adequate, regularly maintained filter or strainer must be installed immediately upstream to catch fine particles before they migrate to the delicate sealing surfaces.

- Respect Flow and Orientation: Do not trust anyone’s verbal installation—always look for the stamped flow direction arrow on the valve body itself. Install it facing the right way. Additionally, try to mount the solenoid valve coil assembly pointing upwards, if the fluid type permits. This simple step keeps internal debris away from the moving plunger axis, assisting longevity and valve setup consistency.

- Wiring Stress Relief: Ensure the wire leading to the coil (or its terminal plug) is not tightly pulled or strained. Strain can pull the wires from their terminal inside the connector, leading to an open circuit or intermittent current problems. Properly crimp the lugs and confirm there’s no way the wires can wiggle loose over time due to machine vibration.

- Voltage Confirmation: Pre-Startup: Once the installation is mechanically sound, verify your electrical check one last time. Test the terminal voltage when the valve is supposed to activate to ensure you are receiving clean power at the correct rating. Doing this simple step before powering the machine saves more coils than any complex feature!

Maintenance Tips to Extend Solenoid Valve Life

Expert solenoid valve maintenance should move from reactive fixing to proactive prevention of sticking and thermal failure. It’s always cheaper to maintain than to replace a seized valve under emergency pressure.

- Temperature Logging and Monitoring: During your routine checks, manually record the temperature of the coil assemblies of high-cycle valves. Any significant jump (say, from 120°F to 150°F on the same spot) signals an issue—it could mean internal friction is slowing the plunger or that a downstream blockage is forcing the solenoid to hold open against extreme pressure, contributing to coil stress and subsequent overheating.

- Scheduled Internal Inspection/Cleaning: For crucial systems, a calendar-driven tear-down and inspection are better than waiting for a failure. De-pressurize the line, carefully disassemble the solenoid core tube, check the seal seats for corrosion or scratches, and confirm the plunger slides freely and without effort.

- Replace Seals Proactively: Do not wait for the “hissing” sound. Set up a schedule to replace the diaphragm and O-rings based on the expected lifespan (time or cycle count) given by the manufacturer for the type of media you use. Using a manufacturer-specified maintenance kit for your valve care is critical to avoid mixing seal materials.

- Address Water/Dirt in Pneumatic Systems: If you operate a high-volume solenoid valve in pneumatic systems, periodically bleed your line separators and ensure all filters are actively managing water and oil mist. Contaminated air is the biggest enemy of pneumatic valve reliability.

With Solenoid Valve vs Without Solenoid Valve

This table demonstrates, through direct comparison, why modern, fluid control systems architecture abandoned reliance on complex mechanical and manual systems decades ago in favor of simple electro-mechanical logic.

Parameter | Control By Solenoid Valve (High Automation) | Without Solenoid Valve (Mechanical Actuators/Manual) |

Media Flow Control | Precise Volumetric Shutoff; ideal for sequencing tasks via digital logic. | Slow, inconsistent control; relies on cams, hydraulics, or physical operator force. |

Response & Speed | Extremely Fast (sub-50ms operation); crucial for fast cycling. | Requires complex hydraulics or bulky actuators to shift; always significantly slower. |

Safety Logic | High—Seamless safety interlocks wired for immediate, guaranteed action upon E-Stop. | Limited—Requires external, dedicated safety hardware to ensure media stoppage. |

Energy Footprint | Low, efficient use of energy only at the moment of valve actuation. | Requires continuous power or pneumatic supply pressure just to maintain its operational state. |

Maintenance Difficulty | Relatively simple—modular design allows for fast coil or core-tube swap-outs. | Complex, multi-stage maintenance of piston seals, rod alignment, and complex piping. |

Real-World Industrial Insight

One final piece of advice that you don’t find in the textbooks is about electrical noise. In vast Industrial Automation systems, the sudden, high current draw (inrush current) required by a large 110V AC solenoid coil to pull in the plunger can create a significant, temporary power disturbance. This transient power dip can sometimes introduce noise back into nearby control circuits, leading to spurious errors. An experienced designer manages this not only by using low-power 24V DC solenoid valves but also by installing proper suppression (such as metal oxide varistors or diodes) directly across the coil terminals of every single valve, preventing electromagnetic feedback. Ignoring this common-sense measure is often the difference between a highly stable system and one plagued by difficult-to-diagnose, intermittent communication issues. This type of detail is vital for trustworthiness and true operational knowledge when dealing with large-scale control environments.

Conclusion — Small Coil, Massive Control

We’ve dissected every angle of the high-performance solenoid valve: its core working principle, the essential classifications, and its unshakeable place as the command center for all solenoid valve for air and fluid control. For system integrators and maintenance personnel alike, recognizing that the efficiency and safety of sophisticated process control valves rely heavily on a small component’s physical integrity is the ultimate lesson.

By applying critical selection criteria, being meticulous during valve setup and installation, and implementing rigorous, preemptive solenoid valve maintenance that guards against the core solenoid valve failure causes (thermal, contamination, pressure-mismatch), ensure system success. This powerful, yet diminutive, electromechanical marvel truly embodies the reality of industrial automation: controlled motion relies on one tiny coil with command authority over the whole operation.

FAQs

Q1: What does a solenoid valve do?

A solenoid valve function is to translate an electrical signal into immediate, accurate valve actuation, primarily to turn off, turn on, or divert the flow of media like air, steam, or liquid. It is a critical remote control component.

Q2: Why is a solenoid valve used in automation?

Solenoid valves are critical in automation because they offer incredibly fast and repeatable operation speeds (in milliseconds), combined with simple electrical connectivity. This allows controllers like PLCs to sequence rapid and synchronized actions with high reliability for flow control.

Q3: Difference between NO and NC solenoid valves?

The difference between normally open and normally closed solenoid valves is simple: A Normally Closed (NC Solenoid Valve) must be energized (powered) to open the flow path, whereas a Normally Open (NO Solenoid Valve) must be energized to close the flow path. Choose NC for most “fail-safe” (close) applications.

Q4: What causes solenoid valve failure?

The main solenoid valve failure causes include applying the wrong voltage which causes the coil to burn out, and physical contamination (dirt or grit) lodging itself on the seat or hindering plunger movement, leading to seal leaks or permanent sticking/locking.

Q5: How long does a solenoid valve last?

A good industrial solenoid valve that has been correctly specified for its load and environment, and that undergoes professional solenoid valve maintenance, can achieve 5-10 million cycles or last between 3 to 10 years, though life is highly variable depending on media and cycle frequency.

Q6: What is a solenoid valve in RO systems?

In many systems, the solenoid valve for air and fluid control is an NC type used as a primary isolation switch. It automatically cuts off the raw water feed line the moment the pure water storage tank sensor reaches capacity, or when the system enters a shutdown sequence, thereby preventing overfill or waste.

Q7: What is a solenoid valve used for?

Solenoid valve applications include: directing air pressure to cylinders in pneumatic systems; precision chemical metering and dispensing; initiating emergency stops on dangerous motion; regulating hydraulic pilot systems; and performing high-cycle fluid diversion tasks across every major manufacturing segment.