Industrial Pressure Gauges: Triclover, Capsule, Homogeniser Comparison

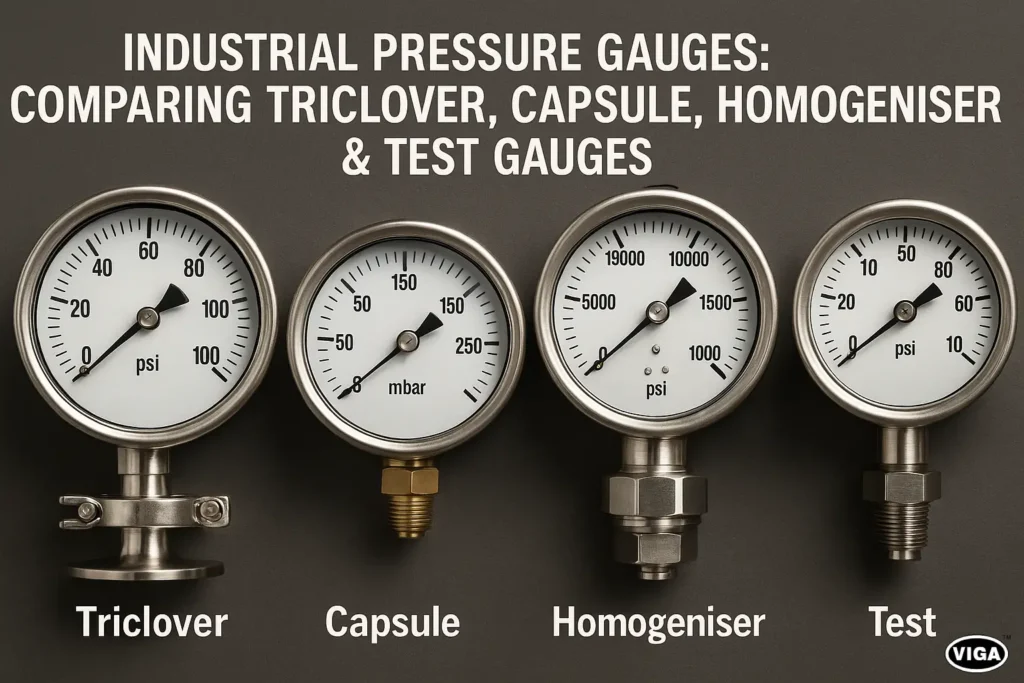

Industrial Pressure Gauges: Comparing Triclover, Capsule, Homogeniser & Test Gauges

Within the complex operational landscapes of manufacturing, processing, and industrial facilities, the capacity to precisely monitor and control system dynamics represents the core of operational excellence. Process stability and safety are inherently dependent on the instrumentation chosen, particularly the measurement of pressure. As such, the selection of the correct measuring device demands careful consideration of not only range and media but also the device’s design intended purpose.

Industrial Pressure Gauges serve as primary safety indicators and critical control loop elements. The fidelity of these instruments dictates product quality, adherence to strict processing recipes, and ultimately, personnel safety. Failure to select the proper gauge can lead to measurement drift, premature component fatigue, and devastating failures in high-risk environments. This necessity explains Why accuracy and calibration matter in industrial applications. Ensuring the gauge’s reading aligns precisely with actual process conditions provides the foundation for safe, compliant, and cost-effective operations.

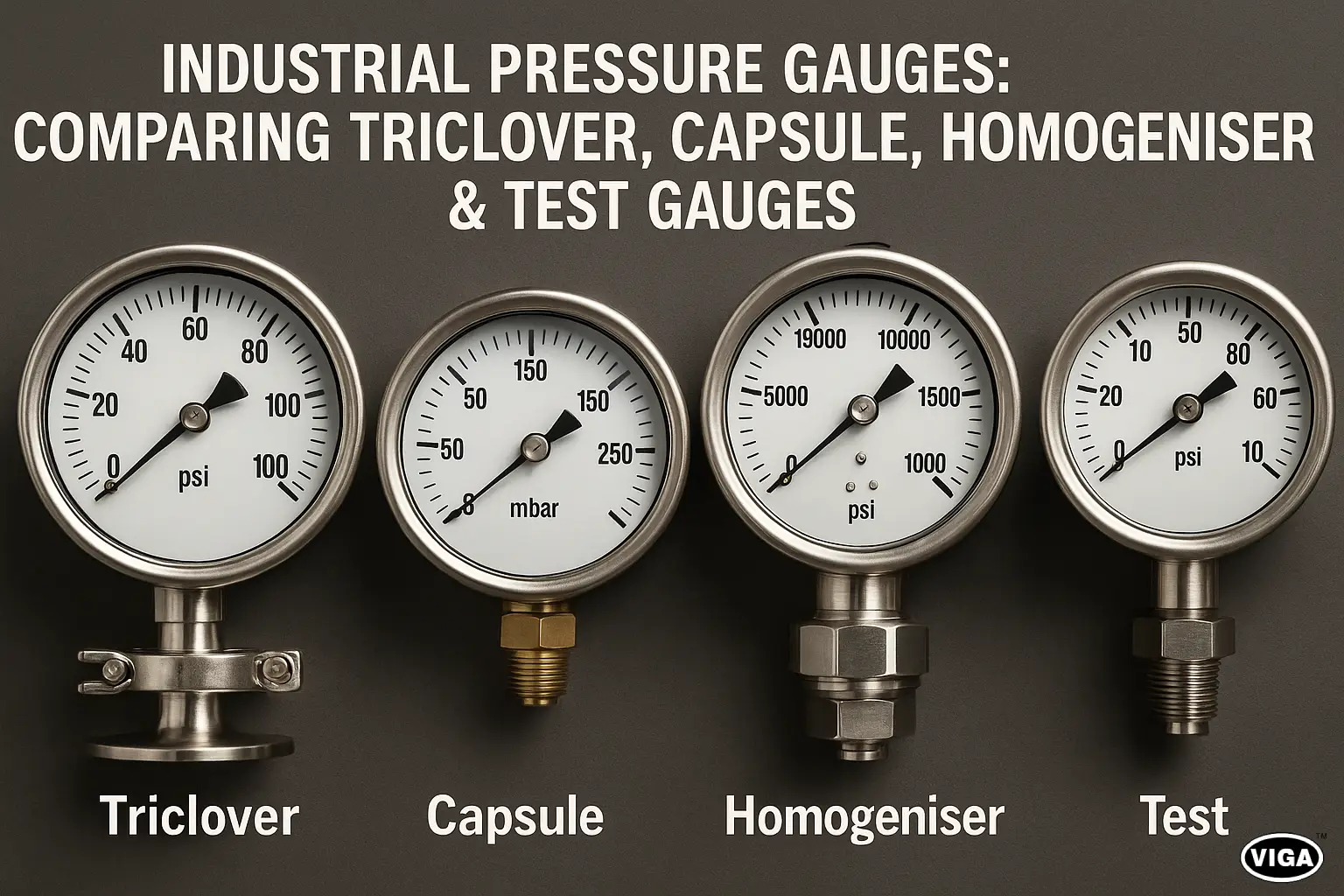

Understanding the specific mechanics and advantages of highly specialized instruments allows industry professionals to make informed procurement and maintenance decisions. This analysis offers a detailed comparative review of the hygienic Triclover Pressure Gauge, the sensitive Capsule Pressure Gauge, the high-endurance Homogeniser Pressure Gauge, and the critical Test Gauge for Calibration. An exploration of these distinct devices illuminates the sheer variety of Types of Industrial Pressure Gauges available to meet any industrial requirement.

What Are Industrial Pressure Gauges?

Industrial Pressure Gauges are indispensable devices designed to convert fluid force exerted on a sensing element into a readable value, typically displayed on a dial scale or digitally. The classical working principle—the mechanical gauge—revolves primarily around the utilization of the Bourdon tube. This C-shaped, helical, or spiral tube, typically forged from bronze or stainless steel, is flattened into an elliptical cross-section and closed at the tip. When process pressure is applied, the tube attempts to return to a circular cross-section, causing the free end to straighten. This minute displacement is magnified by a gear and pinion mechanism, ultimately driving the pointer around a calibrated dial.

The application of these instruments transcends simple observation. Their continuous readings are vital for the efficient and safe execution of various industrial activities across the spectrum, from fine chemical handling and precision food manufacturing to controlling the energy flow in large-scale chemical plants. A well-maintained and calibrated gauge serves as the physical link to established safety limits and Pressure measurement standards. Furthermore, in industries facing high vibration or pressure pulsation, appropriate modifications, such as liquid-filled casings, are utilized to protect the sensitive internal mechanisms and enhance pointer stability, thereby guaranteeing reliable readings even under dynamic operational duress. Proper knowledge of Industrial Pressure Gauge Calibration ensures regulatory compliance and optimal process control integrity.

Triclover Pressure Gauge

The Triclover Pressure Gauge distinguishes itself not primarily by its internal sensing mechanism, but by its distinct connection design. Also referred to by its common industry name, the Triclamp, this sterile coupling facilitates a smooth, crevice-free junction with the process line. This feature is the hallmark of its widespread utility in sectors requiring exceptional levels of sanitary design.

Its function is inherently linked to hygienic applications. When a standard threaded gauge or an exposed diaphragm assembly is utilized, media, contaminants, or microscopic biological materials can become lodged in the tiny thread gaps or sharp corners, making cleaning-in-place (CIP) or sterilization-in-place (SIP) ineffective. The use of a smooth, gasketed seal, clamped by the easy-release Triclover ferrule system, solves this crucial industry challenge. The construction materials invariably consist of high-grade, often electro-polished, Stainless Steel Pressure Gauges (typically 316L). This resistance to aggressive media and rigorous cleaning chemicals is not merely an advantage; it is a fundamental requirement in regulated environments like dairy, pharma, and food/beverage processing.

Advantages central to this design include superior process integration due to easy to clean capabilities, guaranteed reliable sealing through the robust gasket compression, and its inherent corrosion-resistant nature, which prolongs the instrument’s operational life dramatically while maintaining strict sanitary validation. For applications where process cleanliness directly affects consumer safety, the Triclover design offers unparalleled assurance.

Capsule Pressure Gauge

When applications involve the measurement of exceptionally low pressure—differential pressure, draft pressure, or flow in specialized air or gas lines—the traditional Bourdon tube lacks the requisite sensitivity. For such scenarios, the highly sensitive Capsule Pressure Gauge offers the precise solution.

The operational principle of this device centers on an enclosed element known as the capsule, which gives the instrument its name. The capsule is created by welding or soldering together two thin, deeply corrugated diaphragms along their perimeter. This assembly creates an enclosed chamber where pressure from the process media is introduced. As pressure is exerted internally, the sensitive corrugated shape allows for a greater displacement and mechanical stroke even at pressures below 1 psi (or 27 inches of water column). This large, yet sensitive, displacement is then transmitted through a movement mechanism, effectively converting a negligible pressure change into a measurable dial movement.

The Capsule gauges are particularly ideal for gas measurement and filter monitoring applications where extremely minute pressure variations must be registered reliably. They are frequently deployed in laboratories, pharmaceutical isolators, ventilation and air handling units (HVAC), and cleanroom environments where measuring slight low-pressure measurement variations between different controlled zones is necessary for environmental integrity. The primary benefits include their highly accurate reading across a compressed, low-end scale and their simple construction that minimizes fluid contamination in clean environments. Understanding this instrument’s low-pressure capabilities clarifies the notable difference when making a Pressure Gauge Comparison.

Homogeniser Pressure Gauge

The Homogeniser Pressure Gauge is purpose-built to survive and perform under the most brutal conditions found in specialized fluid processing—specifically the homogenization process employed in the dairy and beverage industries. Homogenization involves mechanically breaking down particles (like fat globules in milk) into uniformly small sizes by forcing the liquid at high velocity through a very small, restricted opening at immense pressures, often in excess of 5,000 to 10,000 psi.

This extreme pressure application introduces several engineering challenges. Not only must the instrument withstand the sheer static magnitude of the force, but the system inherently creates violent pulsating pressure surges, rapid cycles of pressure, and intense internal vibration—conditions that destroy a standard gauge movement quickly. The Homogeniser gauge is designed with a robust build incorporating a thickened diaphragm and highly specialized fluid-dampened movements (often using heavy silicone or glycerine filling). The use of heavy-duty materials, often exceeding 316L stainless steel, coupled with integral mechanical dampeners, ensures that the gauge provides precise readings under pulsating pressure, which is critical for product consistency.

Maintenance and calibration best practices dictate that due to the demanding duty cycle, these gauges must be frequently inspected for diaphragm damage or leakage in the internal filling fluid. Because of their continuous exposure to high stress, an emphasis is placed on highly traceable Industrial Pressure Gauge for Dairy calibration procedures to guarantee both product consistency and long-term instrument integrity.

Test Gauges for Calibration

The Test Gauge for Calibration operates at the apex of the pressure measurement hierarchy, serving as a fundamental benchmark tool rather than a constant process monitor. Its core function is not daily monitoring, but acting as a superior reference standard within a facility’s metrology or calibration chains. The accuracy of every other operational gauge, from Bourdon tubes in boilers to the sanitary gauges in filling machines, ultimately depends on being verified against the precise reading of a designated test gauge.

Importance of traceability and accuracy verification cannot be overstated. A test gauge possesses a verifiable certification chain (known as traceability), ensuring its measurement accuracy can be traced back to international primary standards (e.g., NIST). To perform this function, they must adhere to exceptionally stringent Pressure Gauge Accuracy Standards, usually in the 0.25% or 0.1% accuracy class. These high-level specifications necessitate design features aimed at enhancing the precision of reading, such as finer adjustment mechanisms, a mirror-finish scale to prevent parallax error, and high-resolution markings.

The fundamental Difference between operational and test gauges is determined by its purpose and design priority. An operational gauge is built for durability and ease of reading in the process environment. A test gauge, conversely, is built purely for fidelity; it may be less rugged but boasts higher precision and finer adjustment. Facility quality control policies rely entirely on the meticulous use of test gauges to conduct regular accuracy checks and to ensure full compliance with audit requirements. Knowing Why use test gauges for calibration accuracy is understanding the quality management foundation of all pressure monitoring systems.

Triclover vs Capsule vs Homogeniser vs Test Gauges

Distinguishing between these specialized instruments involves more than just a quick comparison; it necessitates an understanding of the critical intersection between measurement technique, process safety, and the environment. Selection is an exercise in identifying the instrument that manages the highest degree of process risk effectively.

The challenge of which gauge suits which industry is a case study in optimization: the sanitary demands of food manufacturing are perfectly met by the quick-clean connections of the Triclover design, making it the most sensible choice for the clean utilities and main process lines within that sector. Conversely, a manufacturer tasked with measuring air filtration rates or atmospheric drafts needs the highly granular detail only the highly responsive bellows of the Capsule mechanism can provide. The homogenization section of a bottling plant needs the sheer structural integrity and vibration suppression of the Homogeniser type. Meanwhile, the facility’s instrument shop or external certification service will maintain a calibrated library of Test Gauges to ensure metrological consistency across all other systems.

Factors to consider before selection must include:

- The Medium: Is it a clean gas, viscous food product, corrosive chemical, or pulsing hydraulic fluid? This dictates the diaphragm seal material or the requirement for a separator.

- The Scale: The operational range dictates the required Bourdon tube configuration or, conversely, whether the extreme sensitivity of a capsule is needed.

- The Consequence of Failure: Critical process loops warrant higher-cost, more accurate gauges that necessitate regular calibration checks using an associated test gauge. The expense of selecting the incorrect Types of Industrial Pressure Gauges almost invariably outweighs the initial purchase savings.

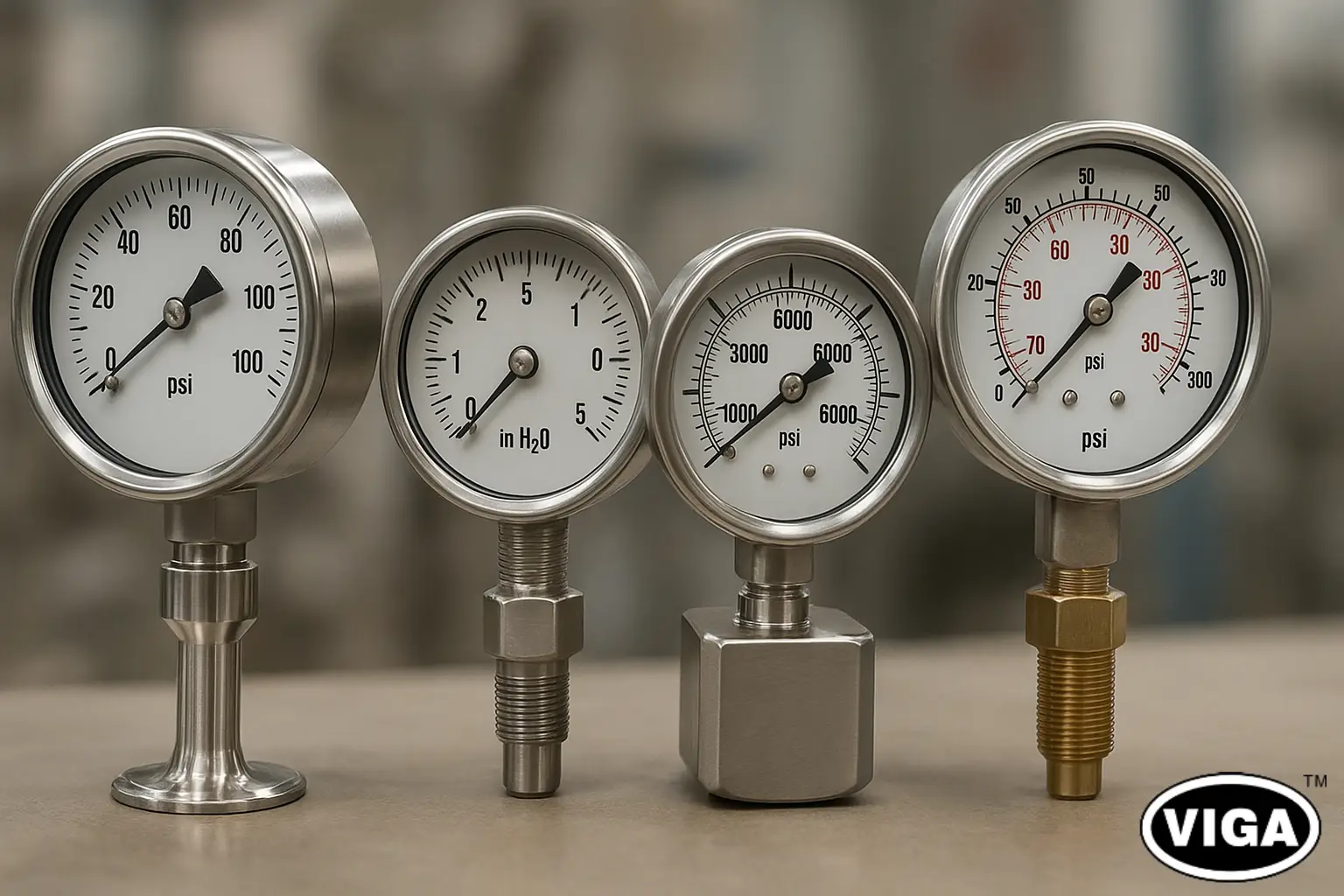

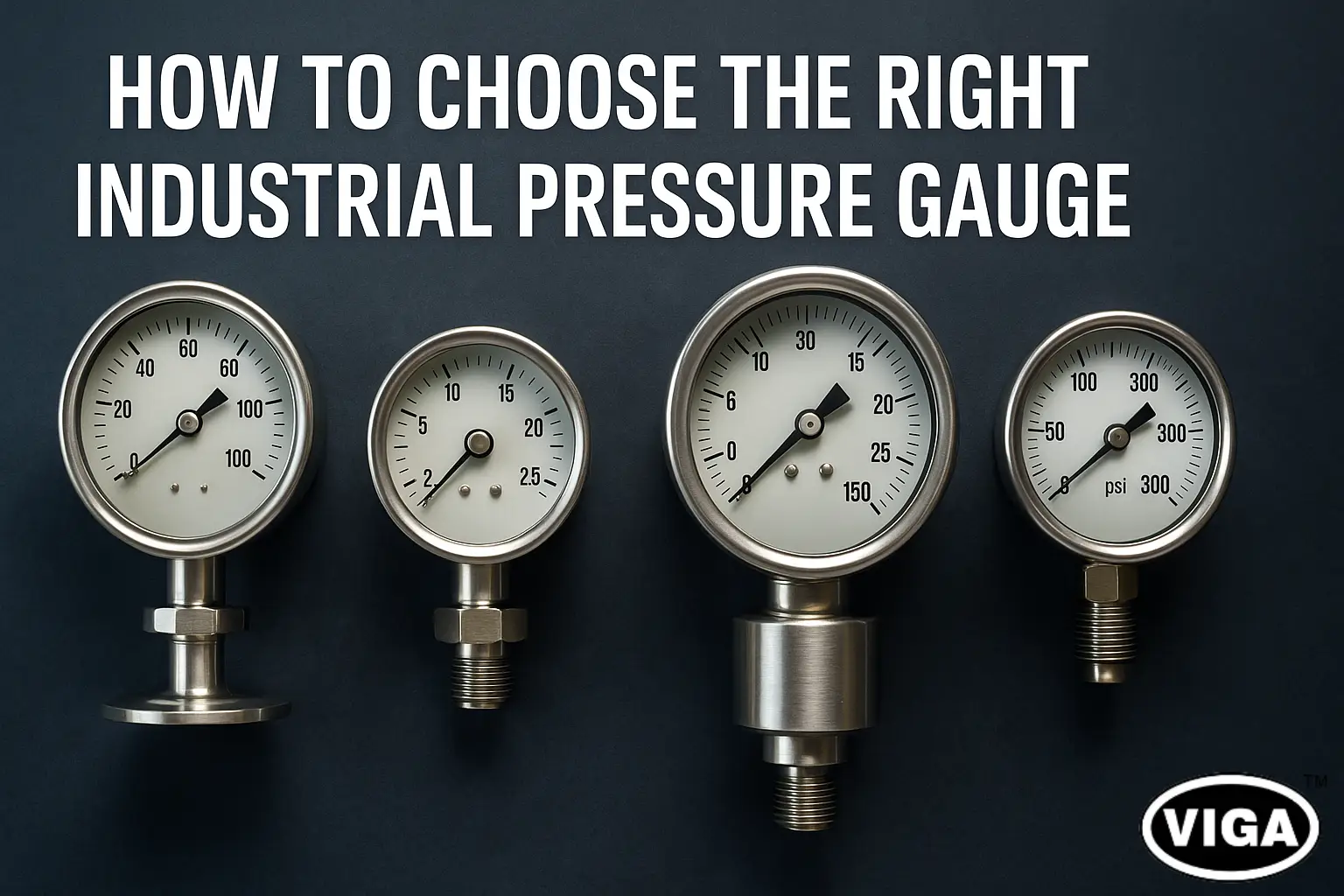

How to Choose the Right Industrial Pressure Gauge

Selecting the correct pressure gauge is a decision requiring structured technical analysis to ensure system safety and maximize operational lifespan. The instrument chosen must stand up to both the normal and transient operating conditions of the specific application.

The primary and perhaps most critical determinant is establishing the process pressure range. Conventional practice dictates that the nominal range of the selected gauge should be approximately double the normal process pressure maximum (the “2X rule”). This critical safety factor protects the instrument against temporary overpressure events and ensures optimal Accuracy Requirement since Bourdon tube reliability often degrades closer to its scale maximum. Following this, the physical and chemical characteristics of the media type must be rigorously evaluated. If the fluid is highly corrosive, highly viscous, or likely to crystalize or foul the Bourdon tube opening, a Diaphragm Seal must be utilized, requiring a Stainless Steel Pressure Gauges wetted body constructed of a resistant alloy.

External considerations related to Environmental conditions are equally paramount. Excessive vibration mandates the selection of liquid-filled (glycerin or silicone) cases, which dampen pointer movement and reduce wear on the gears. Temperature is also a key concern; an ambient process that exceeds specified limits requires an attached siphon or pigtail to dissipate heat, preventing component damage. Lastly, the chosen gauge should have an established routine for Maintenance and calibration frequency dictated by its criticality, thus keeping control systems operating effectively and maximizing its useful operational time as the Best Pressure Gauge for Industrial Use.

Common Applications Across Industries

Industrial specialization dictates the specific measurement equipment deployed. The varied conditions encountered necessitate instruments with distinct features capable of handling unique constraints.

- Dairy and Food Processing: This sector is heavily dependent on hygienic standards, making the Triclover Pressure Gauge essential for both high-pressure flow lines and auxiliary monitoring. The continuous sanitation protocols demand rapid installation and disassembly, which the Triclamp system facilitates perfectly. Furthermore, high-pressure equipment like pasteurizers and homogenizers require the specialized robustness of the Homogeniser Pressure Gauge to maintain operational continuity under shock loads.

- Chemical and Petrochemical Plants: This application sphere primarily concerns media safety and extreme process conditions (high temperature and high pressure). Here, gauges must be integrated with robust diaphragm seals composed of highly specialized corrosion-resistant alloys, isolating the sensing element from volatile or aggressive substances like concentrated acids.

- Pharma Manufacturing Units: Extreme purity is the ruling constraint. Equipment used often must feature pharmaceutical-grade Stainless Steel Pressure Gauges surfaces and must avoid all threaded process connections. These critical environments use Capsule Pressure Gauge variants for cleanroom monitoring alongside the high-purity Triclover assemblies for the formulation and purification processes.

- Calibration Labs: These facilities do not engage in constant process monitoring but rather act as verification centers. They rely exclusively on certified Test Gauges for Calibration, sometimes using precision Deadweight Testers, to ensure every working gauge returning from a process environment meets documented accuracy standards before redeployment.

Conclusion

The field of Industrial Pressure Gauges reveals a vast spectrum of instruments, each painstakingly engineered to resolve a specific industry measurement challenge. From the seamless hygiene facilitated by the Triclover connection and the nuanced measurement capacity of the Capsule type, to the enduring structural resilience of the Homogeniser, and the verifiable precision inherent in the Test Gauge for Calibration, each tool is a specialist designed to master a particular operational domain.

A comprehensive Pressure Gauge Comparison highlights that successful instrumentation procurement is defined by the depth of application analysis. Correct instrument selection moves beyond simple functional requirement checks; it embodies a calculated assessment of process fluid, potential contaminants, temperature, dynamic loading, and safety tolerances. Ultimately, the careful selection of the right pressure gauge provides crucial assurance of process efficiency, contributes directly to the prevention of expensive downtime, and most critically, ensures the maintained safety and integrity of the overall processing system. For any critical operation, choosing a gauge optimized for the specific challenges faced remains an engineering imperative.

FAQs

Q1: What is the most accurate type of industrial pressure gauge?

The gauge built explicitly for the highest level of metrological certainty is the Test Gauge for Calibration. These instruments possess accuracy ratings ranging from 0.25% down to 0.1% of the full-scale span, making them the most precise mechanical pressure indicators used as reference standards in professional industrial and laboratory settings.

Q2: Why are test gauges essential for calibration?

Test gauges are essential because they provide a highly precise, verifiable measurement standard with certified traceability to international standards. This rigorous accuracy enables technicians to measure and confirm that every permanently installed, operational gauge within the plant provides readings that adhere to required safety and quality assurance protocols, making them critical for regulatory compliance and safety (Why use test gauges for calibration accuracy).

Q3: Which gauge is best for dairy and pharma industries?

The Triclover Pressure Gauge is considered the optimal choice for the dairy and pharmaceutical industries. Its design is centered around the quick-release sanitary clamp (Triclamp) connection, eliminating internal crevices and simplifying the thorough cleaning processes (CIP/SIP) that are mandatory for these highly regulated, hygienic sectors.

Q4: How often should industrial pressure gauges be calibrated?

While there is no single mandated universal time frame, a majority of industries schedule Industrial Pressure Gauge Calibration checks at least once annually. However, highly critical gauges subjected to severe process stress (vibration, extreme temperatures, or frequent pressure cycling) should be calibrated every six months to guarantee their continuous operational fidelity and safety.

Q5: What is the difference between Triclover and Capsule gauges?

The defining difference between these instruments lies in their area of specialization. A Capsule Pressure Gauge is engineered with a sensitive element for exceptionally accurate measurement of very low pressure (draft, static air). The Triclover Pressure Gauge, in contrast, is specialized for medium-pressure sanitary applications where its unique clamp connection design ensures media separation and ease of hygienic maintenance.