Why Your Air Compressor Needs the Right Air Filter

Let’s start with a foundational, critical fact that is often missed in the chaos of the shop floor: Your machinery lives or dies by the quality of its air.

Think about your own lungs—they require clean, filtered air to survive and function optimally. Now, translate that necessity to your complex industrial system. For the industrial world, the compressed air supply is an omnipresent utility, the literal engine behind countless operations. The crucial comparison here is immediate and profound: If humans can’t survive polluted air, neither can your compressor.

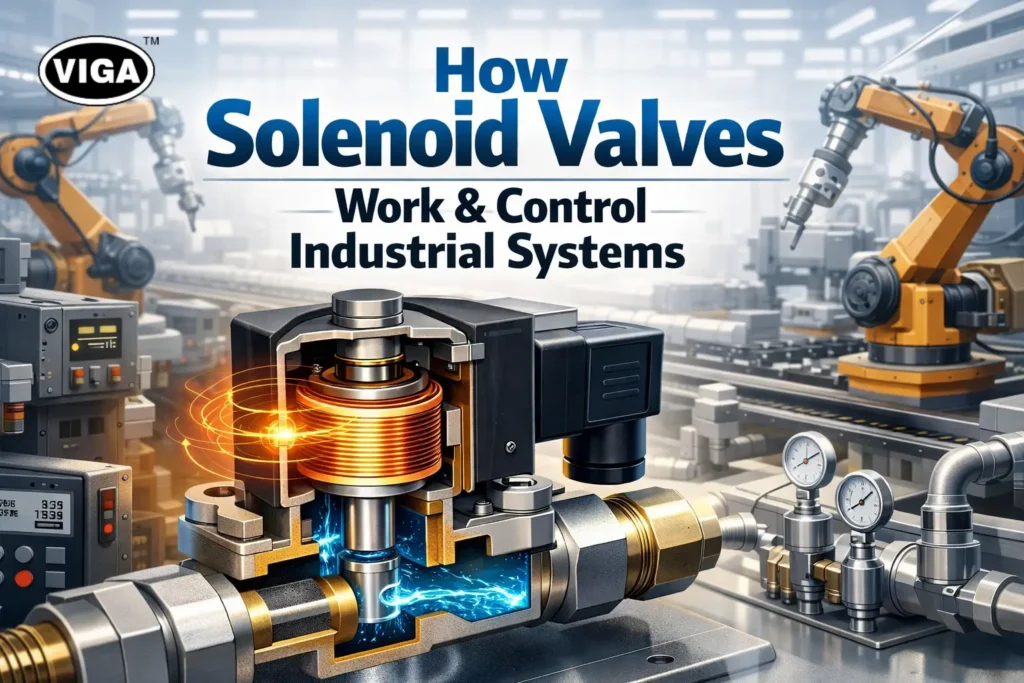

We see the damage all the time: that high-value CNC machine whose valves are sticky, that sudden spike in abrasive dust clogging a critical high-precision solenoid. This is the handiwork of dirty compressed air, the subtle saboteur lurking in the lines. The only thing standing between microscopic, corrosive filth and your most expensive equipment is the unsung hero—the Air Compressor Filter.

Take, for instance, a large factory where metal filings and water vapour are drawn in every second. When those impurities meet high pressure and move into the pneumatic valves, it inevitably results in damaging wear and unplanned downtime. This happens because why compressor needs air filter isn’t simply about capturing dirt—it’s about preserving a controlled operating environment. Neglecting a robust compressor air filtration strategy is choosing risk over reliability. In this guide, we cut through the confusion and explain exactly why and how your filtration strategy determines your company’s uptime and financial health. A perfectly functioning, long-lasting system must deliver demonstrably clean compressed air—that much is certain.

Why Clean Air Matters in Compression Systems

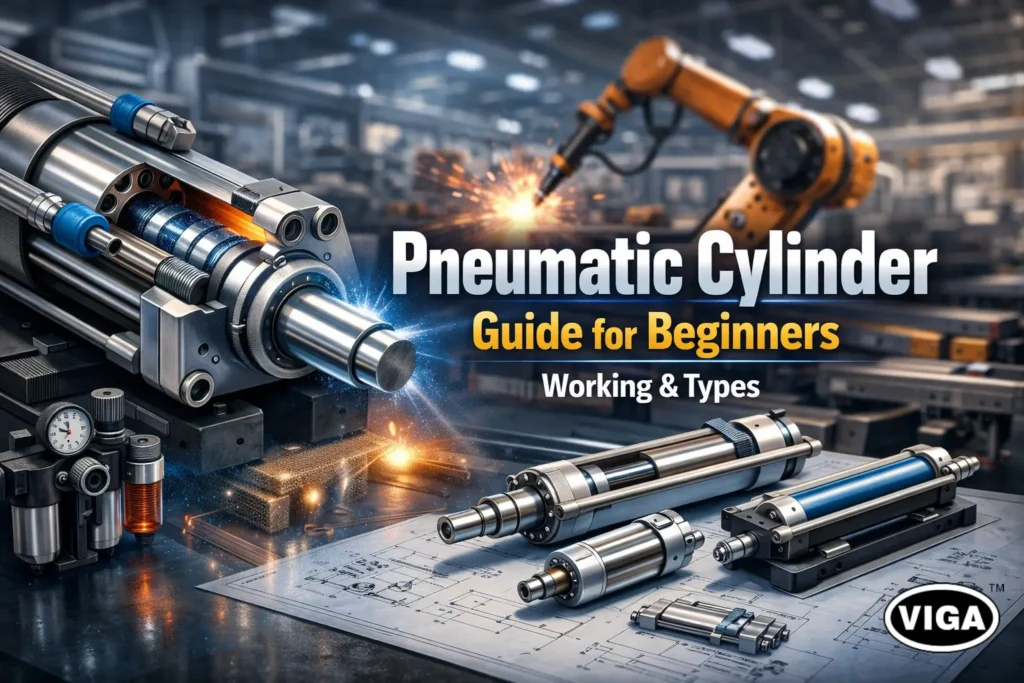

We rely on compressed air so fundamentally that we often stop thinking about what it actually is. It’s often referred to as the “industrial oxygen”, indispensable power that drives robotic actuators, sorting lines, and material handling systems. Yet, air that enters your system is rarely pure; it’s loaded with everything from local street dust to pollen, and worst of all, latent moisture.

Here’s the danger: as the air volume is crushed from atmospheric pressure to the required system pressure, those atmospheric contaminants become intensely concentrated. The parts per million of moisture and dust is multiplied, effectively turning a mild atmospheric irritant into a corrosive, damaging cocktail inside your equipment.

The real cost comes in the hidden breakdown that results in the costly effects of dirty compressed air. You get:

- Rusting components as water condenses downstream.

- Clogs formed by fine particulates and condensed oil aerosols.

- Wasted energy fighting back-pressure and flow restriction.

An operation’s credibility and bottom line hang in the balance, requiring an immediate elevation of technical due diligence, what experts call a solid compressor air filtration program.

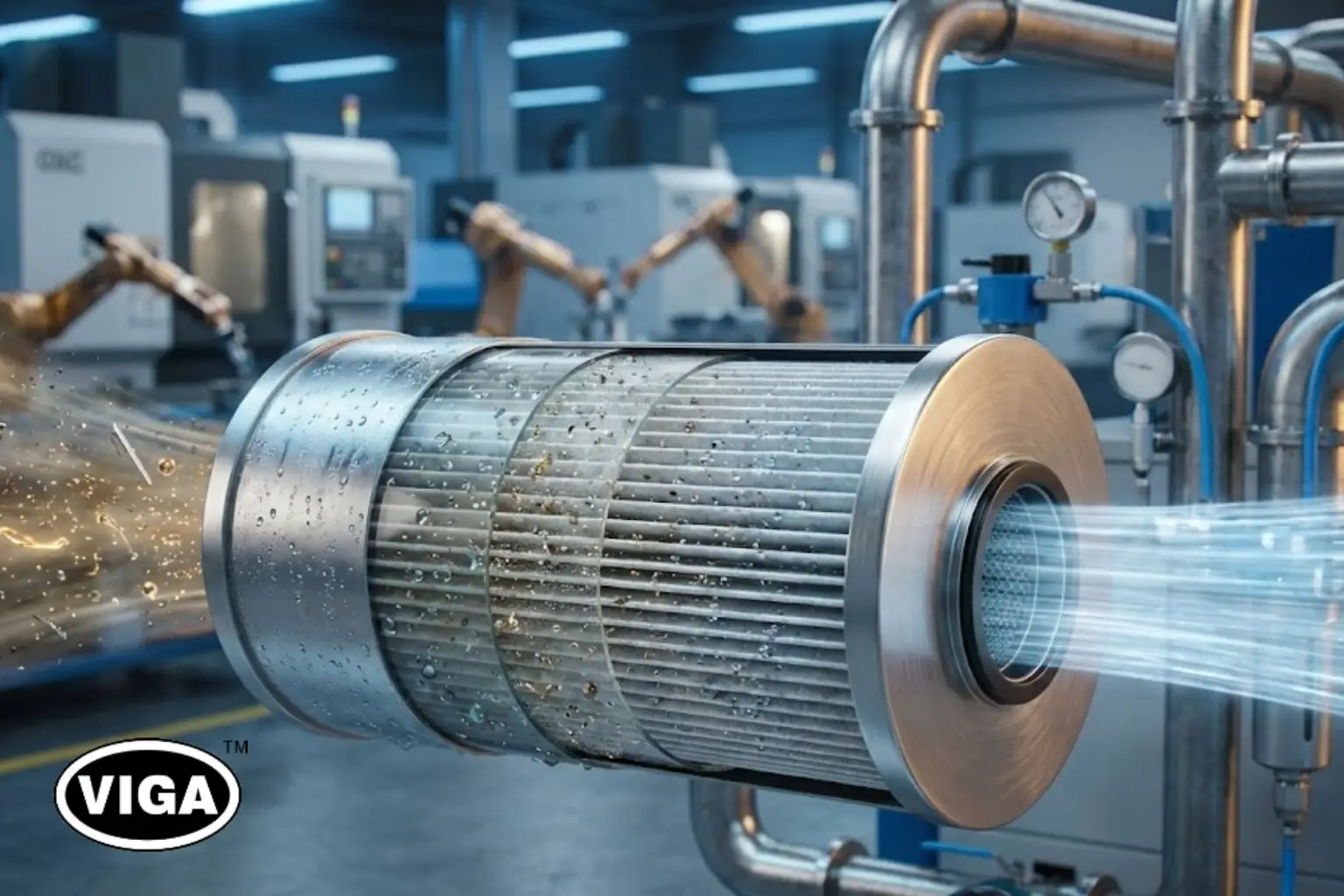

What Exactly Is an Air Compressor Filter?

If your compressor is the engine, the Air Compressor Filter is the specialized guardian standing between the volatile outside environment and your critical tools. It is, perhaps, most easily visualized as a super-industrialized version of your kitchen’s coffee filter, tasked with far more complex particle removal and chemical capture.

What is the main role of an air compressor filter?

Its three-fold primary purpose is: capturing solids, facilitating moisture separation, and adsorbing oil and solvent vapors. It isn’t merely a physical screen, but an engineered separator.

In the physical setup of a Clean Compressed Air System, you don’t typically see just one filter; you see a ‘filter train.’ Filters are intentionally placed downstream from the compressor’s receiver tank. Why there? Because the compressed air needs time to cool down. As it cools, the hot vapour quickly turns back into liquid water (condensate and aerosols). It is far more efficient for the modern Air Compressor Filter to deal with liquid droplets and sticky residues than try to scrub pure gas. That staged, strategic installation is fundamental to running a professional Compressed Air System.

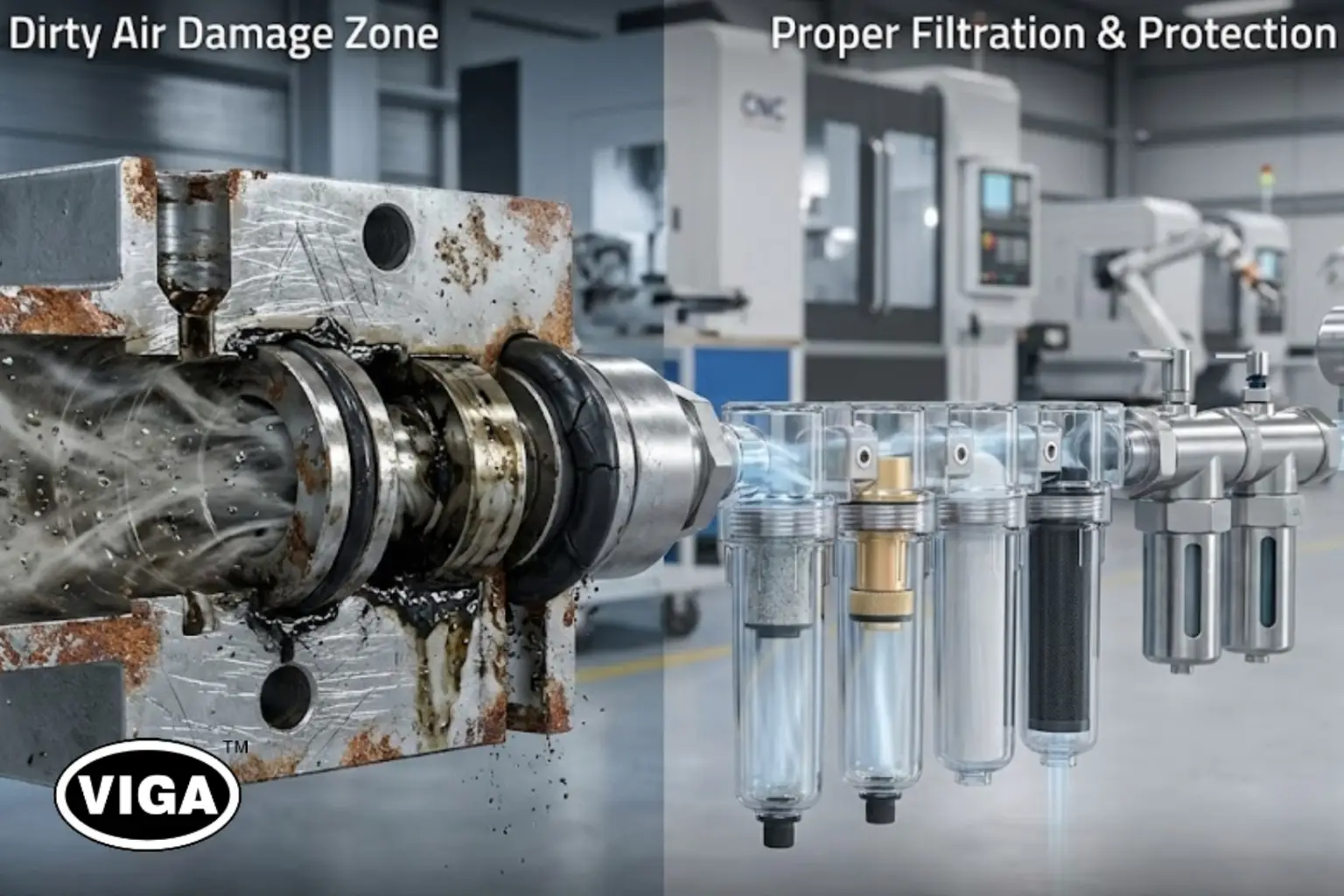

How Dirty Air Damages Your Compressor & Pneumatic Tools

When air contamination breaks through your primary defenses, the process moves instantly from productive function to guaranteed destruction. This rapid breakdown demonstrates why paying for clean air is simply smarter than paying for replacement parts. The problem boils down to abrasive damage and systemic clogs, both leading to catastrophic component stress.

- Internal Component Seizure and the Sandpaper Effect: Fine dust and dirt aren’t filtered, but they’re accelerated. They create a “sandpaper effect” inside air-driven components, increasing friction on critical seals, pistons, and rotors. The result? Premature wear, reduced stroke consistency, and seals that start leaking precious pressure. This mechanical damage confirms why clean air is so vital—otherwise, it’s instant Compressor Damage.

- The Ruin of Seals and O-Rings: High heat and consistent exposure to contaminated water condensate drastically accelerates the degradation of rubber and plastic seals. This failure manifests as countless, expensive leaks throughout your system. Once air is leaking, your system’s required run time increases exponentially to compensate, undermining overall compressor efficiency.

- Rapid System Failure and Clogging: Perhaps the most frustrating immediate Effects of Dirty Compressed Air is system stalling. Oil aerosols that condense in cool air lines combine with dust to create sticky sludge. This thick grime jams and obstructs the fine tolerance control components within critical spool and pilot valves, leading to near-immediate pneumatic system failure that requires hours of troubleshooting and manual valve teardown.

- Negating Tool Reliability: Let’s be honest: if you want to know how air filters protect pneumatic tools, look at the replacement bills. Unfiltered, dirty air voids warranties because manufacturers know that moisture and grime erode the finely tuned lubrication within an air tool, causing motors to bind up and bearings to rust prematurely, confirming that using Dirty Compressed Air on precision tools is financially suicidal.

Types of Air Compressor Filters

Any expert will tell you: if your filtration system uses a single element to do a complex, multi-layered job, you’ve set yourself up for early failure. Filtration systems rely on a tailored, step-by-step approach. Types of air compressor filters must be selected based on the specific type of impurity you are trying to mitigate, showcasing a depth of professional Expertise.

Filter Type | Primary Action / Location | Contaminant Target | Rationale for Use |

General Particulate | First stage (bulk pre-filter). | Large solid particle removal (dust, rust, dirt). | Protects the more delicate, high-value filters downstream. |

Coalescing (General Duty) | Middle stage. | Oil aerosols, condensed water, and fine solids (up to 0.1 Micron). | The workhorse for mandatory moisture separation and oil-aerosol control. |

High Efficiency Coalescing | Fine final stage (often downstream of the dryer). | Ultra-fine sub-micron aerosols (best for paint or critical components). | To meet critical, very low tolerance (Class 1) purity standards. |

Activated Carbon (Vapour) | Final, post-filtration stage. | Odors, volatile hydrocarbon vapors, chemical scents. | Mandated when air is used near or on food/medical products. |

When you are specifying an Industrial compressor air filter, the golden rule is “start coarse, end fine.” This progressive approach means the cheapest, bulkiest filters are constantly protecting the expensive, ultra-fine elements, maximizing the element life of your whole system.

Why Your Compressor Needs the Right Filter

If there’s a single core takeaway, it’s that an air filter is not an accessory, but a non-negotiable insurance policy that pays you back in savings and stability. Understanding the real importance of an air compressor filter is understanding its direct impact on profitability.

- Direct Energy Cost Savings (The Big Hidden Winner): A clean air line operates with minimum flow resistance. An improperly specified or clogged filter element immediately chokes the air supply, leading to significant back-pressure and system flow loss. Your compressor fights this blockage, running longer cycles and consuming substantially more electricity to keep the required working pressure up—drastically reducing compressor efficiency and needlessly driving up your utility bill.

- Product Quality and Reject Minimization: Whether you are molding medical plastics, finishing wood surfaces, or spray-painting metal parts, contamination is instantly visible on the final product. Clean, dry air is paramount to quality control, offering measurable benefits of clean compressed air in reduced rejection rates and superior finishes.

- Mandatory Regulatory Security: In sensitive sectors (pharma, medical gas, food contact), air quality is non-negotiable. It must meet an auditable, quantifiable standard based on particle size, water, and oil. These ISO 8573 air quality classes categorize required air purity levels. Filtration isn’t optional; it’s a must-have for regulatory compliance and avoiding ruinous legal fallout.

- Preservation of Costly Assets: We can’t emphasize enough: The filter cartridge is always cheaper than the actuator, robot end effector, or tool motor it is tasked to protect. Why clean air is essential for compressor performance simply boils down to extending the life of your most critical assets.

How to Choose the Right Air Compressor Filter

Specifying the correct components for Clean Compressed Air System involves shifting focus from initial purchasing price to the total cost of ownership. When choosing the right air compressor filter, you must adopt an engineering mindset based on required purity, not maximum savings.

- Calculate Your Necessary Air Purity Level: Do not overshoot or undershoot. First, check your tool, end-product, or machine specification: which of the ISO 8573 air quality classes must you meet (e.g., Class 5 shop air vs. Class 1 food-grade)? This mandatory purity defines the element grade you must install.

- Size Against Your Maximum Flow Rate: This is where errors frequently occur. Filters should be sized to accommodate your compressor’s maximum-rated CFM (or M³/min), not just your average use. Undersizing the filter element guarantees an early life pressure drop, making the filtration itself counterproductive to energy saving.

- Analyze the Working Pressure and Contaminant Load: Different pressures affect element density and effectiveness. Likewise, if your environment is extremely dusty (cement works, dusty machining), you may need pre-filtration rated far above what a simple intake filter can handle, sometimes dictating the Best air filters for industrial air compressors is actually a dual-stage arrangement.

- Consider Operating Cost (Pressure Drop): Be smart about energy efficiency. Look at the manufacturer’s spec for the pressure drop across a new filter. Lower initial pressure drop means better long-term compressor efficiency.

Signs That Your Compressor’s Filter Needs Replacement

Any filter system will become saturated over time—that is, after all, their job. Knowing the specific Signs your compressor air filter needs replacement prevents saturation from turning into total component failure. Pay close attention; your system is literally talking to you.

- Excessive Gauge Tattling (Differential Pressure): The most critical sign is an excessive and ever-growing disparity between the filter’s inlet pressure and outlet pressure. A continuous 8 to 10 PSI or higher pressure differential is a dead-giveaway that the filter element is saturated, restrictive, and choking off the supply.

- Moisture or Liquid Appearing at the Tools: Suddenly seeing puddles or droplets forming in drain ports or spitting through an air gun? This catastrophic moisture separation failure means your element has been fully compromised, allowing liquid water and oil to flow freely downstream.

- Strange, Overpowering Smells: If you utilize an Activated Carbon filter for sensitive tasks (food, electronics) and you start noticing a clear, unpleasant hydrocarbon smell in the air—the carbon bed has hit full capacity. It’s time for an urgent replacement to prevent system compressor contamination.

- The Compressor Cycles Unnecessarily: Your compressor unit may seem noisier, or run for longer cycles than normal for the same job. This reduction in the system’s useful flow is a sign of internal restriction—i.e., the clogged filter is forcing the entire system to run inefficiently just to maintain necessary air delivery.

Maintenance Checklist

Air Compressor Maintenance of your filtration line is genuinely low-effort but pays off disproportionately in system reliability and sustained compressor efficiency. Good filter care is defined by proactive inspection, not reactive fixes.

- Establish a Visual and Data Inspection Schedule: Visually inspect all filters, drains, and indicators daily. Most critically, log the reading of the differential pressure gauge (input vs. output) on a set frequency. Monitoring pressure drop over time is key; a sharp jump signals immediate replacement.

- Scheduled Element Replacement: Adhere strictly to the manufacturer’s suggested replacement window—typically between 6,000 to 8,000 operational hours, or every 12 months—even if the pressure drop seems low. Time and continuous element stress degrade its filtering integrity. Do not rely solely on the gauge; a scheduled element change is your failsafe.

- Draining and Cleaning Practices: Regularly drain filter bowls of collected fluid. When replacing elements, ensure the filter housing is cleaned thoroughly, preventing any old sludge or compressor contamination from quickly damaging the brand new element.

- Stock Correct Spare Parts: Only How to maintain an air compressor filter is effective when the new element is exactly the right replacement part. Keep a correctly sized and graded filter element available in your inventory so replacement is immediate when needed.

Comparison Table

Factor | Operating System Without Filter | Operating System With Right Filter |

Air Quality | Poor (High Particulate, Oil, Moisture) | Clean (ISO 8573 air quality classes Achievable) |

Pneumatic Tool Life | Short (Rapid wear, seized parts, pneumatic system failure) | Long (How air filters protect pneumatic tools ensured) |

Breakdown Risk | High (Clogging, Corrosion, Unplanned Stops) | Low (Consistent output, predictable operations) |

Efficiency | Low (High energy waste from pressure loss) | High (Compressor Efficiency is maximized) |

Maintenance Cost | High (Unscheduled labour and component replacement) | Low (Cost is confined to planned preventative element change) |

Real-World Industry Use Cases

The requirement for verifiable Clean air solutions for compressed air systems validates a vendor’s Authority. The high cost of failure across these specialized industries proves the indispensable value of the Industrial compressor air filter.

- Food and Beverage Contact Air: Direct food contact (e.g., propelling powdered products, opening filling nozzles) must meet zero oil content and sterile particle removal requirements. This usually means not only a coalescing filter but an absolute depth filter combined with activated carbon to prevent bacterial growth and any hydrocarbon taste—avoiding ruinous product recall and fines.

- Electronics and Pharmaceutical Cleanrooms: When handling micro-components or preparing sterile packaging, the slightest speck of dust or liquid residue will instantly ruin the batch. Air in this environment is audited for ISO Class 1 compliance. Anything less is immediately detected and costs thousands in wasted inventory.

- High-Gloss Automotive Painting: This is an industry where perfection is visible. A single tiny droplet of oil or water mist in the air line leaves an unfixable defect (“fisheye”) in the expensive paint, often resulting in sanding the piece down and starting the entire high-labour process over. Dedicated ultra-high-efficiency filtration systems protect the entire operation from this expensive human error, ensuring only pure, dry air is applied.

- Critical Process Air (E.g., Medical Gas): Air supplied for patient respiration is legally required to meet the highest safety standard, far beyond standard industrial compressor air filter capabilities. Failure is catastrophic. The reliance on validated filtration here speaks to the ultimate level of necessary purity.

Conclusion

The central theme here is durability and smart operation. You’ve invested heavily in the infrastructure that produces your clean compressed air; the simple, cost-effective step is ensuring that this investment is protected at every pressure drop point.

Choosing the right Air Compressor Filter and diligently executing Air Compressor Maintenance is the non-negotiable step to maximizing asset life and financial returns. Do not treat your filter as a minor utility item. Treat it as the core security against downtime, inefficiency, and contamination risk. By installing and maintaining the appropriate filters—ones correctly sized and graded for your air purity level—you are ensuring your pneumatic system can be relied upon, day after day, year after year. Invest in purity, because ultimately, a clean supply line means a clean balance sheet.

FAQs

Q1: What is the main role of an air compressor filter?

The main and foundational role of an Air Compressor Filter is to act as a preventative measure against costly compressor contamination by systematically achieving simultaneous particle removal and moisture separation of liquid aerosols and vapours, which safeguards every component in the system and validates the Benefits of clean compressed air.

Q2: How often should compressor filters be replaced?

The industry standard dictates replacing filtration elements either every 6 to 12 months (or 6,000-8,000 operational hours) as preventative Air Compressor Maintenance, or immediately when monitoring the differential pressure gauge indicates a critical level of restriction. This constant monitoring pressure drop prevents significant flow loss and the Signs your compressor air filter needs replacement will typically show up here first.

Q3: Can I run a compressor without a filter?

You can, but you absolutely should not. What happens when an air compressor runs without a filter is not if but when immediate and accelerated system destruction occurs. Within weeks, seals will leak, critical components will clog or jam, tools will degrade, and you risk a total pneumatic system failure, severely eroding the benefits provided by how air filters protect pneumatic tools in a controlled environment.

Q4: What type of filter is best for industrial compressors?

For general high-demand use, the Best air filters for industrial air compressors are often a minimum dual-stage arrangement. This involves a dedicated general Particulate Filter for solid dirt and scale, followed immediately by a fine-grade Coalescing Filter. The coalescing filter is essential for superior moisture separation (oil and water) that enables your system to reliably meet the basic requirements of the ISO 8573 air quality classes.

Q5: What happens if air quality is not controlled?

Failure to control air quality is an invitation to costly systemic issues: rampant air leakage due to seal damage, decreased system efficiency because of fouling (a choked line demands more energy), and poor output product quality (e.g., defects in finished goods). For regulated industries, failing to meet the mandated air purity level can lead to complete regulatory failure, fines, and expensive product recalls—confirming why proper filtration is mission-critical.